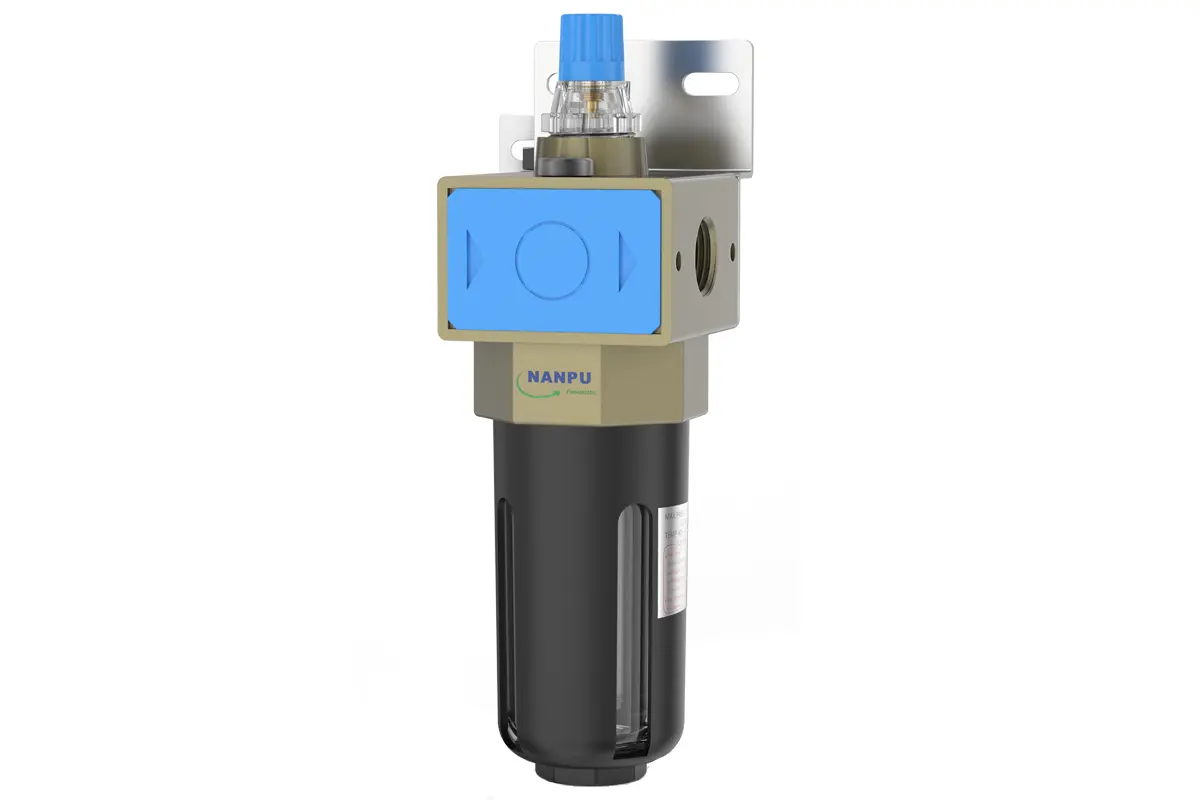

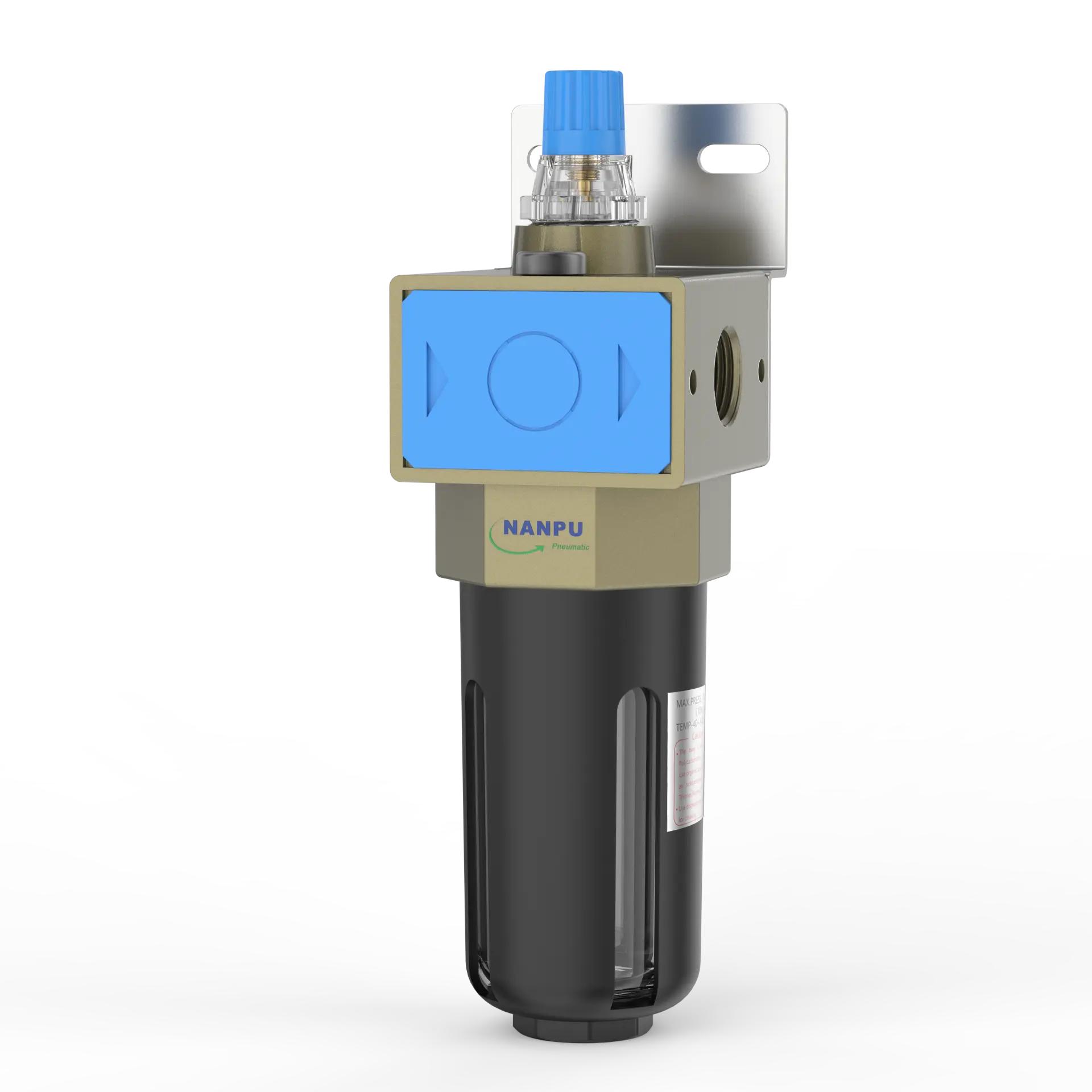

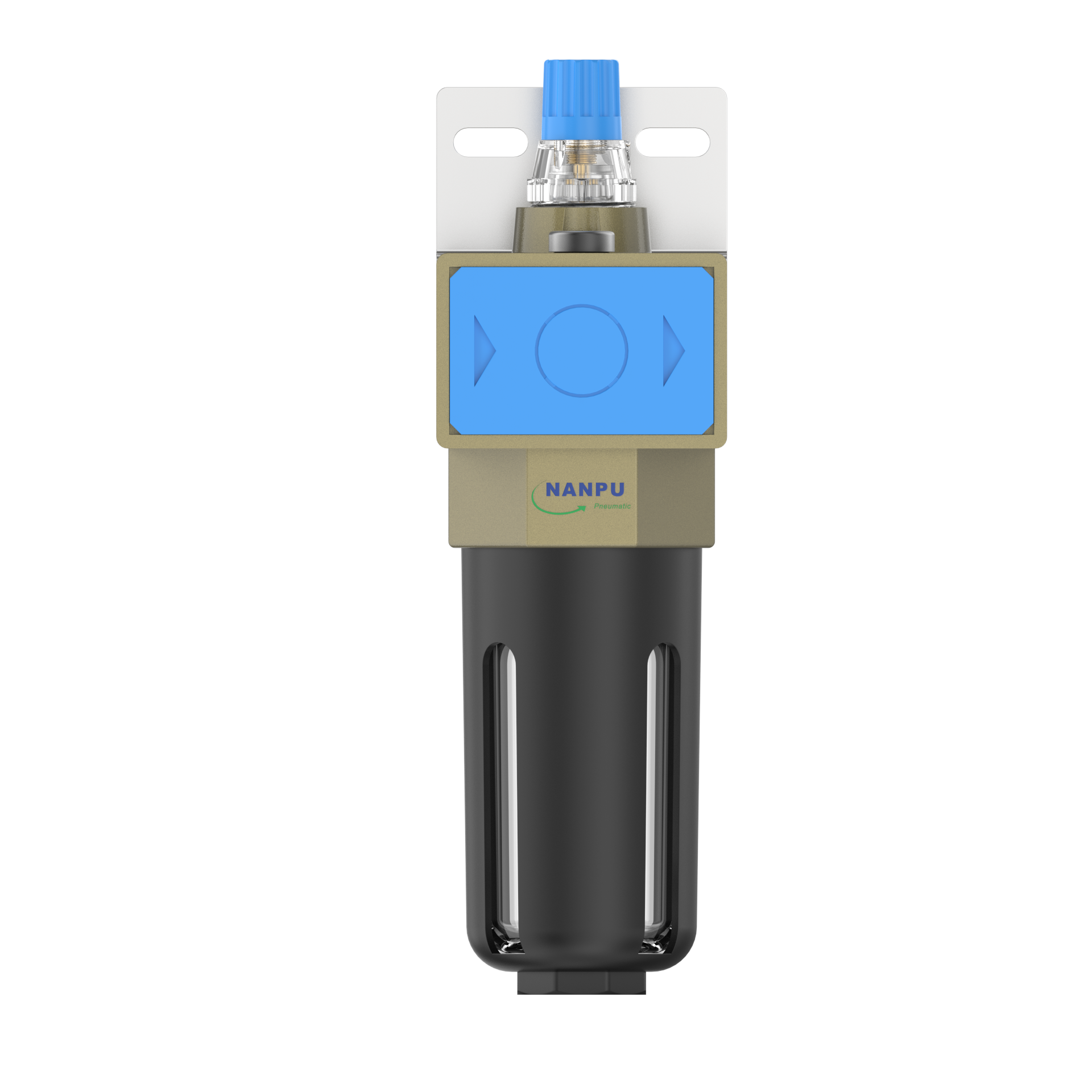

UL-02;03;04 1/4" 3/8" 1/2" UL Air Lubricator

description1

UL-02;03;04 1/4" 3/8" 1/2" UL Air Lubricator

UL-02;03;04 1/4" 3/8" 1/2" UL Air Lubricator

NANPUUL-02;03;04 1/4" 3/8" 1/2" UL Air Lubricator

| UL | 03 | BSP |

| Series Number | Port Size | Thread Type |

| 02:1/4" | BSP | |

| 03:3/8" | NPT | |

| 04:1/2" | PT | |

| 06: 3/4" |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | -5~60℃ |

| Pressure Range | UL 0.05~0.85Mpa(0.51~8.7kgf/cm² )/0~125Psi |

| Bowl Material | Polycarbonate |

| Suggested Oil | Turbine Oil No. 1 ISO-VG32 |

| Model | Specification |

| UFR/-02 | 2080 |

| UFR/-03 | 2100 |

| UFR/-04 | 2600 |

| Product Benefits |

| Almost all pneumatic tools perform better when lubricated with oil.Injecting an oil mist into the air-stream which powers them can continuously lubricate valves,cylinders,and air motors for proper operation and long service life. |

NANPUPreparation

All calibration assemblies shall be manufactured and integrated in strict conformance with the maximum flow rate specifications delineated in the technical documentation. This compliance is imperative for guaranteeing the system’s peak performance, efficiency, and operational dependability. Rigorous adherence to these specifications during integration ensures the system functions within defined parameters, mitigating the risk of inefficiencies or failures arising from non-conformance with maximum flow rate prerequisites.

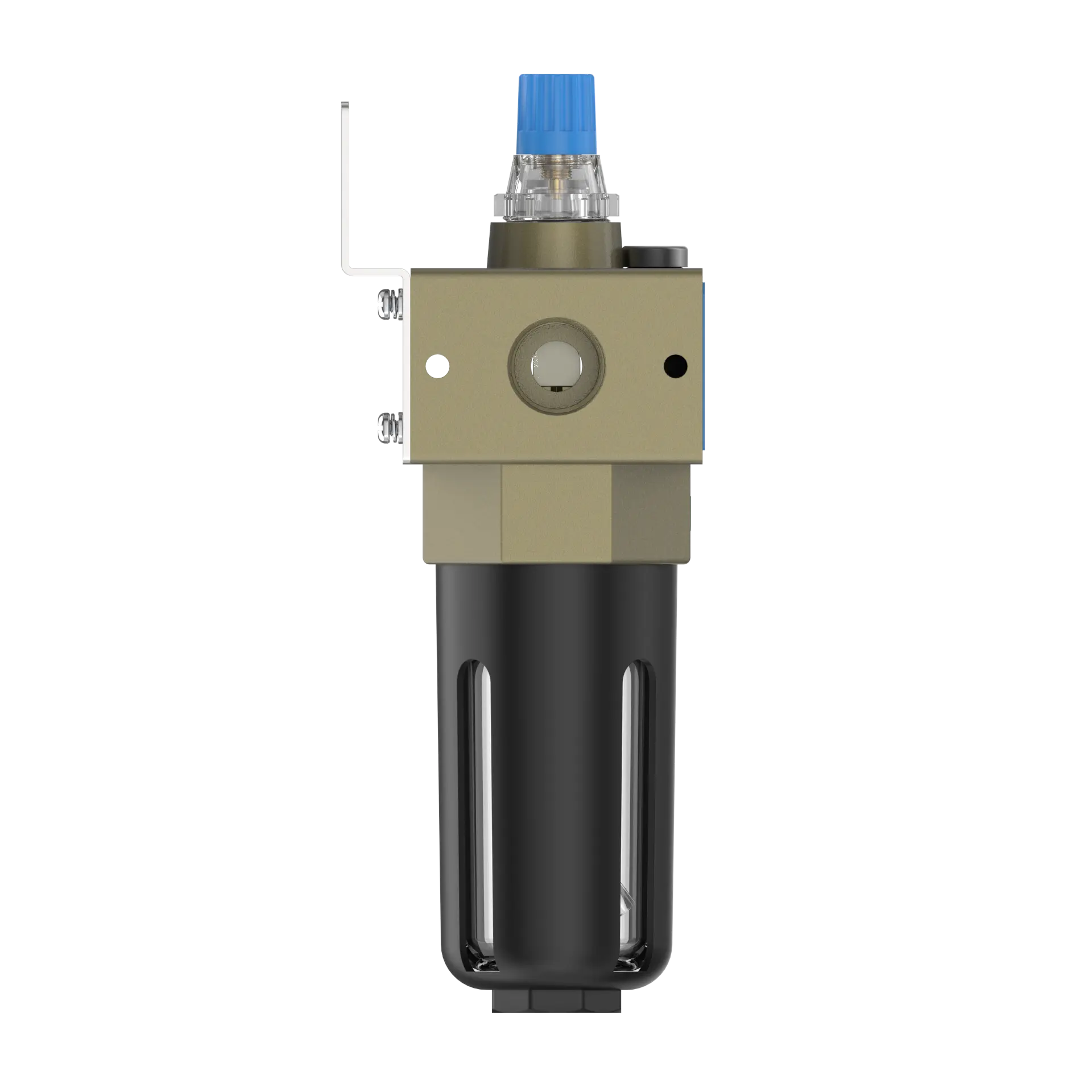

To adjust the oil feed rate, turn the needle valve. A clockwise rotation—aligning with the "+" direction marked on the valve—will progressively increase the oil feed rate. This modification enables quicker oil admission, which might be essential to optimize lubrication under certain operational scenarios. Conversely, rotating the needle valve counterclockwise (the "−" direction) will gradually reduce the oil feed rate. Continuous rotation in this direction can eventually stop the oil feed process. This accurate control mechanism allows operators to precisely calibrate oil flow to the system’s exact needs, ensuring efficient operation and preventing over-lubrication or under-lubrication—both of which can cause equipment wear, inefficiency, or breakdown.