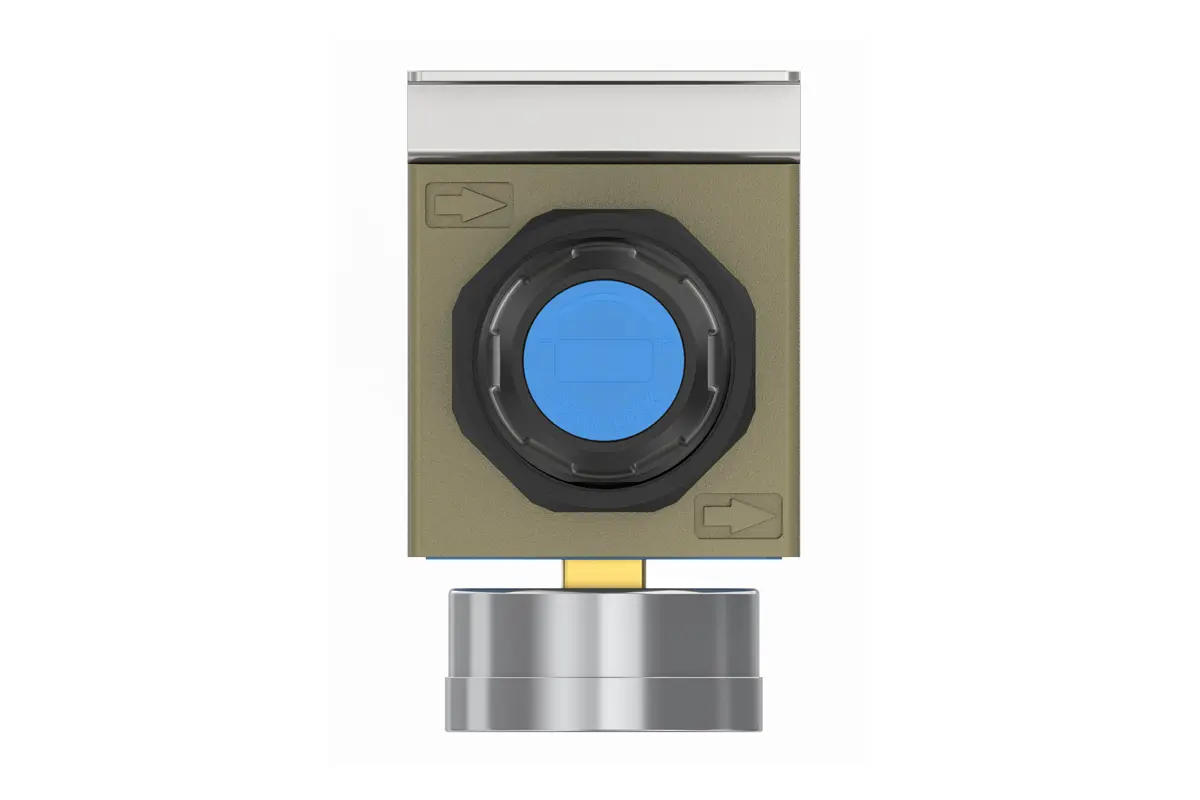

UFR-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

description1

UFR-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

Manual Drain UFR-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

Auto Drain UFR-02D;03D;04D 1/4" 3/8" 1/2" Air Filter, Regulator

NANPUUFR-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

| UFR/L- | 03 | BSP | D |

| Series Number | Port Size | Thread Type | Drainage Method |

| 02:1/4" | BSP | Blank: Differential Pressure Drain | |

| 03:3/8" | NPT | A: Manual Drain | |

| 04:1/2" | PT | D: Auto Drain | |

| 06: 3/4" | |||

| 10: 1" |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | 5~60℃ |

| Filtration Accuracy | 0.01μm、 5μm、40μm |

| Bowl Material | Polycarbonate |

| Pressure Range | 0.05~0.85Mpa(0.51~8.7kgf/cm² )/0~125Psi |

| Model | Model | |

| Manual Drain | Auto Drain | (L/min)Rated Flow Rate |

| UFR-02 | UFR-02D | 2080 |

| UFR-03 | UFR-03D | 2100 |

| UFR-04 | UFR-04D | 2600 |

| Product Benefits |

| All Portsize Piggyback Air Filter (5 Micron Element Standard), Regulator & Lubricator (FRL) |

| Dry Air, Pressure Regulating & Lubricate Air |

| Temperature Range: 41-140℉ (5-60℃) |

NANPU Installation and Operating

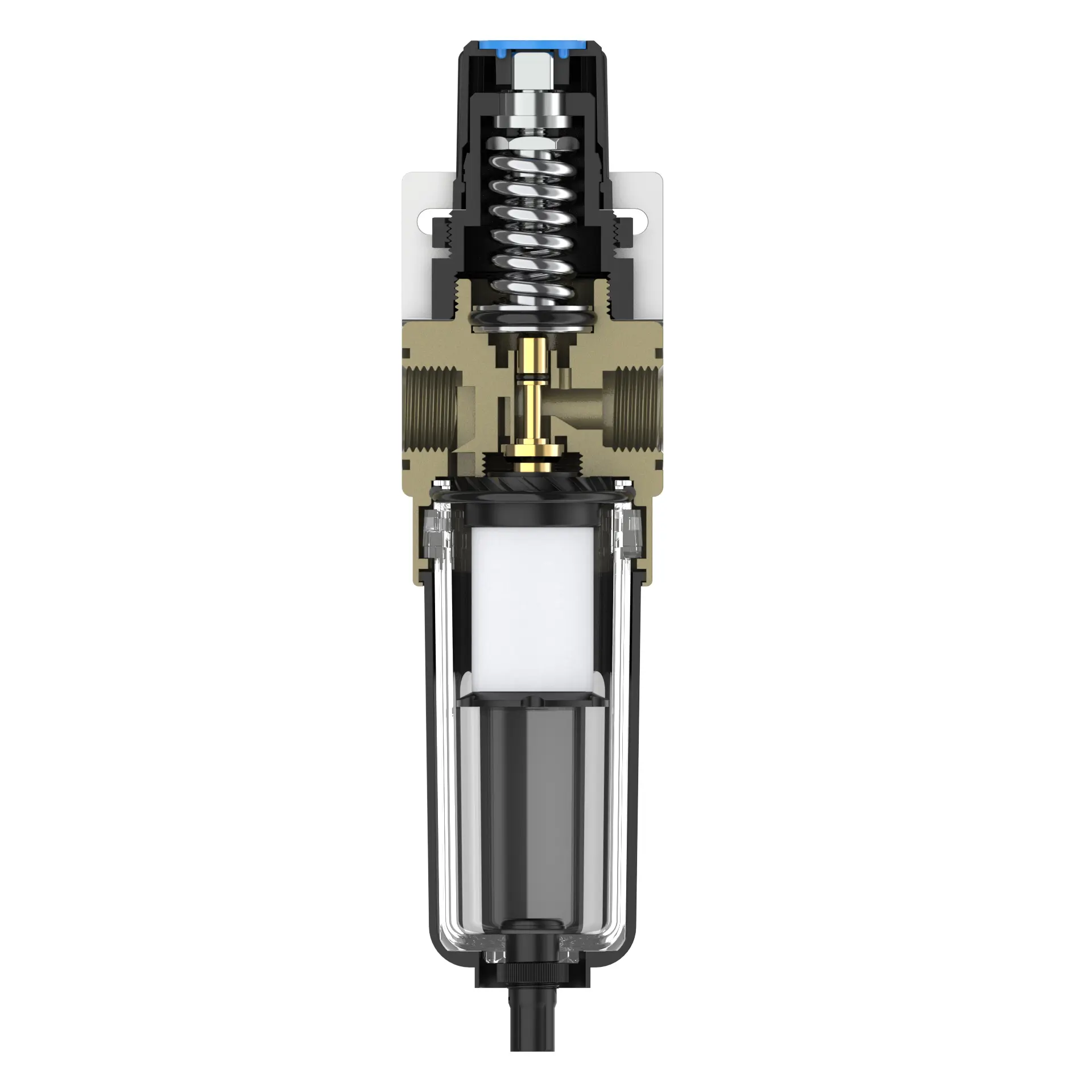

"1.Preparation

All calibration assemblies shall conform to the maximum flow rate specification.

Prior to installation, ports and fittings shall be meticulously degreased and cleaned to prevent particulate ingress into the air conduit.

Confirm that the air flow direction corresponds with the arrow indications on the product housing, and ensure precise matching of port configurations and thread specifications."

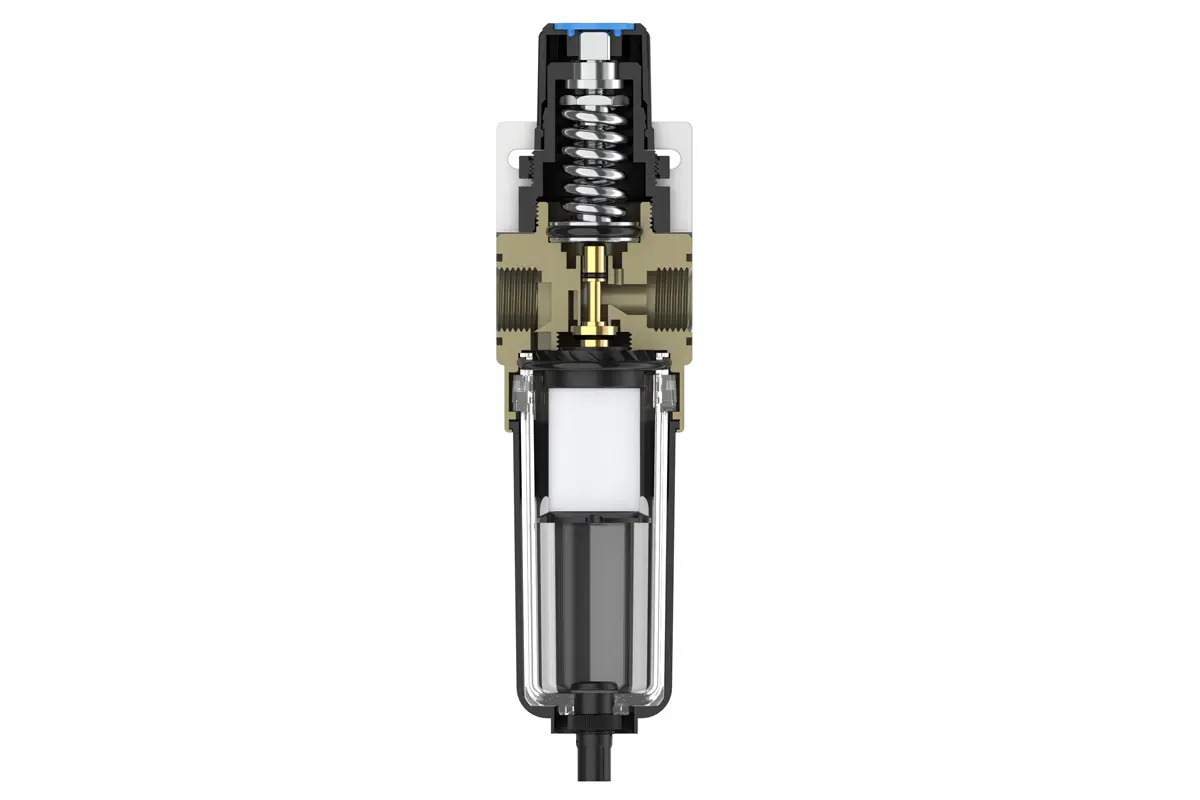

"2. Pressure Adjustment

Lift the pressure gauge knob and initiate rotation. A clockwise turn effectuates a gradual, uniform pressure increase, whereas a counterclockwise rotation induces pressure decrement. Upon reaching the target pressure value, discontinue rotation and firmly engage the knob lock. Failure to secure the knob properly may lead to leakage anomalies, compromising system integrity.

"

5-Micron Brass Filter Element: Demonstrates exceptional filtration efficiency, prolonged service life, and reusability.

0.5 and 0.01-Micron Filter Elements: Effectively eliminate submicron contaminants.

The drainage column incorporates an automatic actuation system, which opens to discharge condensate in the absence of pressure and seals during airflow. Should the water level exceed the specified maximum threshold, immediate drainage is mandatory; failure to do so will substantially degrade dehumidification performance."

"4.Drainage

The drainage column incorporates an automated actuation mechanism, which opens to discharge condensate in the absence of pressure and seals during airflow. When the water level reaches or exceeds the preset upper limit, immediate drainage is required; failure to comply will result in compromised dehumidification performance.

The fitting on the drain head functions as an air hose connection interface and may be disassembled in accordance with operational specifications or system configurations. "

Utilize an appropriate wrench to torque the fittings to the specified torque value to prevent leakage. During initial installation, an air emission may occur, which is not a leak but rather a result of the pressure differential between the interior and exterior, necessitating the release of entrapped air. In such cases, allow the system adequate time to achieve pressure equilibrium, after which it will operate optimally.