UF-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator Air Filter

description1

UF-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

UF-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

NANPUUF-02;03;04 1/4" 3/8" 1/2" Air Filter, Regulator

| UF | 03 | BSP |

| Series Number | Port Size | Thread Type |

| 02:1/4" | BSP | |

| 03:3/8" | NPT | |

| 04:1/2" | PT | |

| 06: 3/4" | ||

| 10: 1" |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | 5~60℃ |

| Filtration Accuracy | 0.01μm、 5μm、40μm |

| Bowl Material | Polycarbonate |

| Pressure Range | 0.05~0.85Mpa(0.51~8.7kgf/cm² )/0~125Psi |

| Model | Model | |

| Manual Drain | Auto Drain | (L/min)Rated Flow Rate |

| UF-02 | UF-02D | 2080 |

| UF-03 | UF-03D | 2100 |

| UF-04 | UF-04D | 2600 |

| Product Benefits |

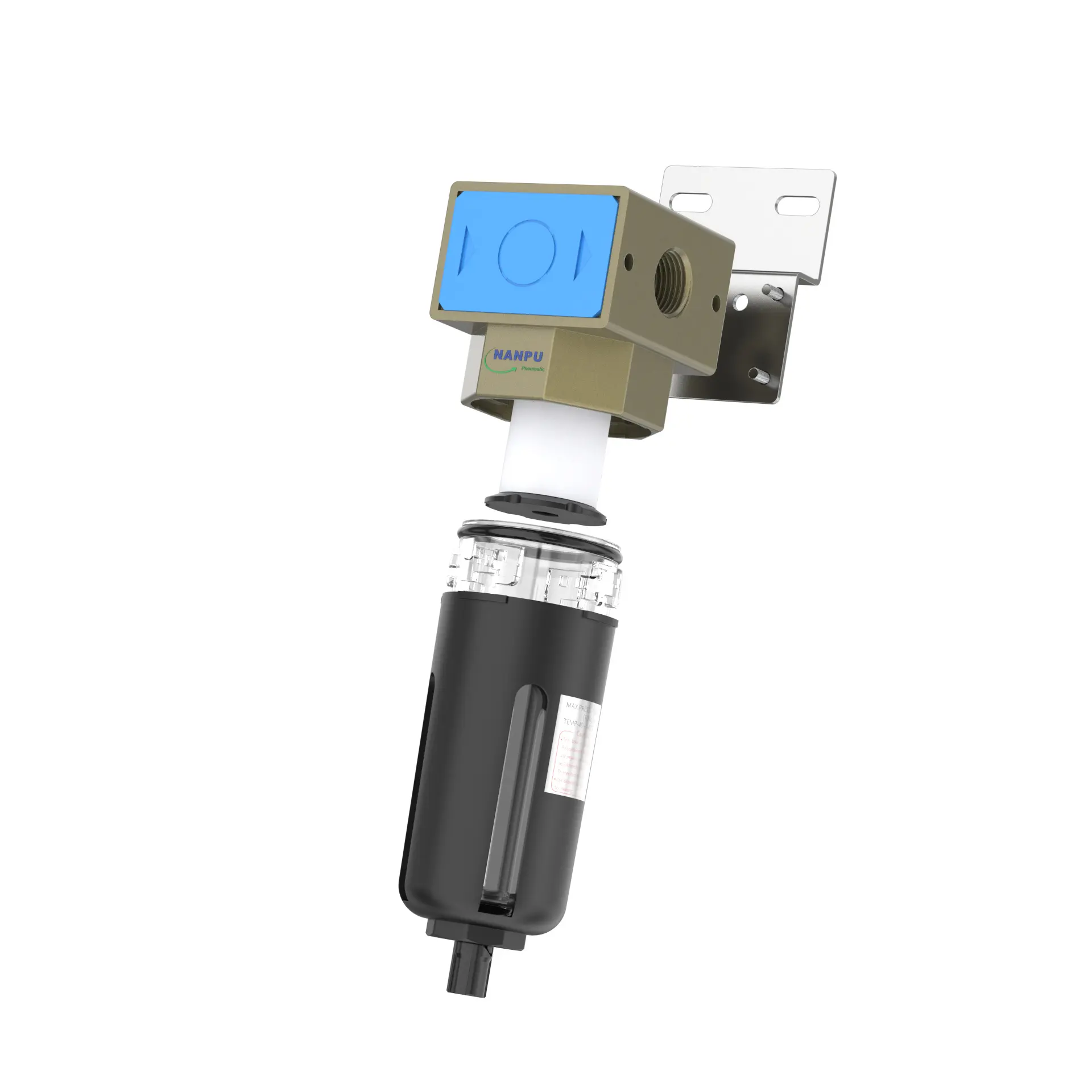

| The assembly of all calibration shall meet the maximum flow requirement. Please clean the port and fitting before installation, it will effectively avoid bring dust to the air path. Pay attention to direction of air flow and arrow pointing on product body if correct, minding port and thread size if match. |

NANPUPreparation

All calibration assemblies shall be meticulously fabricated and integrated to fully conform with the maximum flow rate specifications. Such compliance is critical for ensuring the system’s optimal functionality and dependability. Prior to installation, it is imperative to thoroughly degrease all ports and fittings using approved solvents and tools. This procedure effectively mitigates the ingress of dust and particulates into the air pathway, precluding potential obstructions. During installation, carefully validate that the airflow orientation corresponds with the directional indicators on the product housing and ensure precise matching of port dimensions and thread specifications to guarantee a secure, hermetic connection.

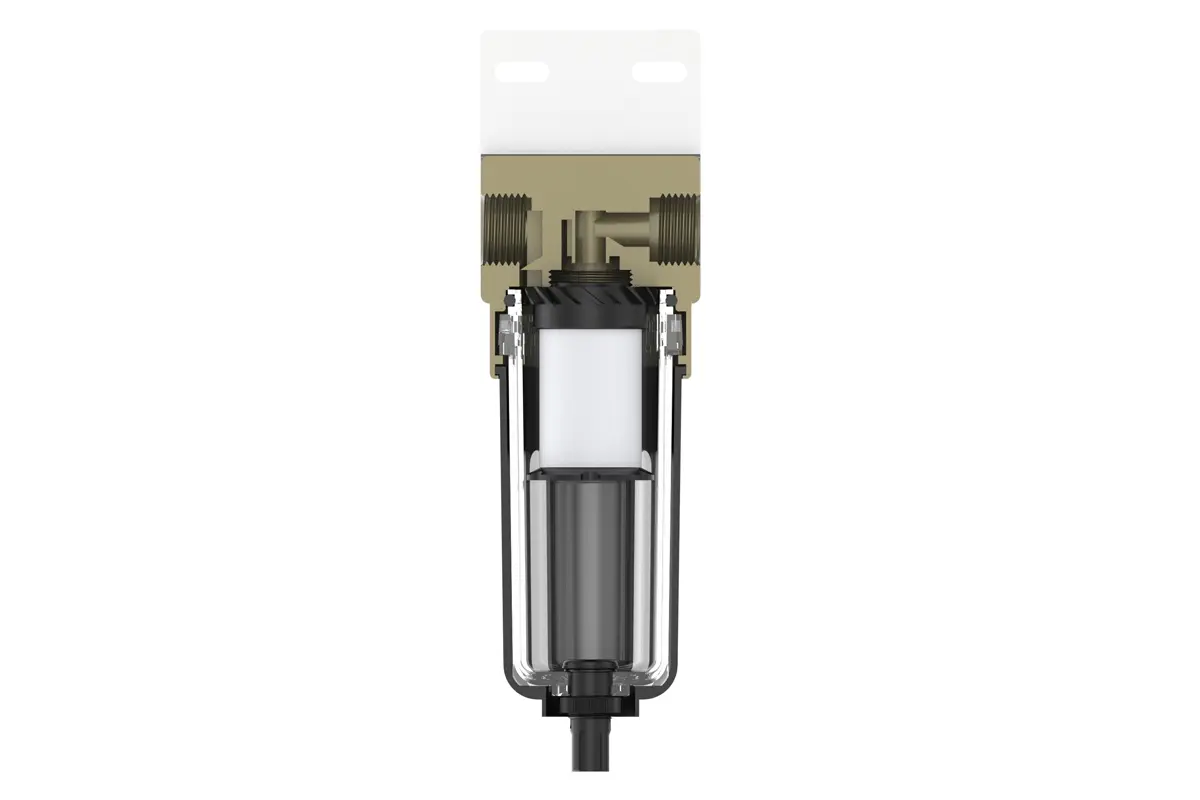

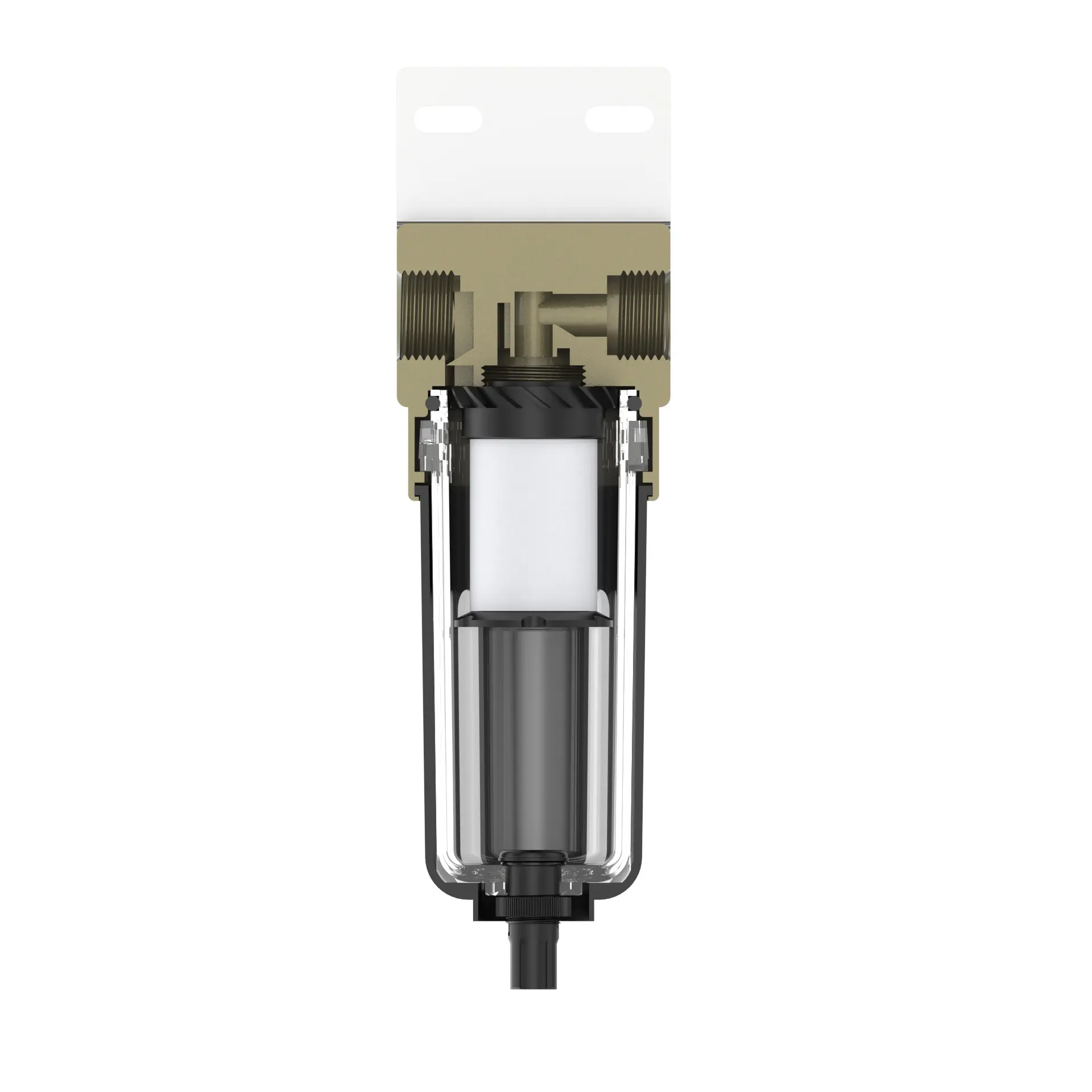

The filtration process is administered via an automated system, employing sophisticated mechanical and filtration technologies to ensure uniform and efficient purification. The 5-micron filter element, a critical component of this system, utilizes a precision-engineered multi-layer architecture. It effectively intercepts and eliminates diverse contaminants, including sediment, suspended solids, colloids, rust, and other particulate matter entrained in the air stream. This meticulous filtration not only protects downstream equipment but also ensures the delivery of high-purity, clean air that complies with rigorous industrial standards.

NANPUDrainage

The drainage column incorporates an automated actuation system. In the absence of air pressure, it triggers the drainage sequence to expel accumulated condensate, mitigating waterlogging risks. During compressed air flow, the column achieves a hermetic seal to preserve system integrity and prevent backflow. Critical to operation is monitoring the column's water level: if the level surpasses the pre maximum threshold, immediate manual drainage is mandatory. Neglecting this can result in diminished dehumidification efficiency, potential damage to downstream components, and compromised overall system performance.