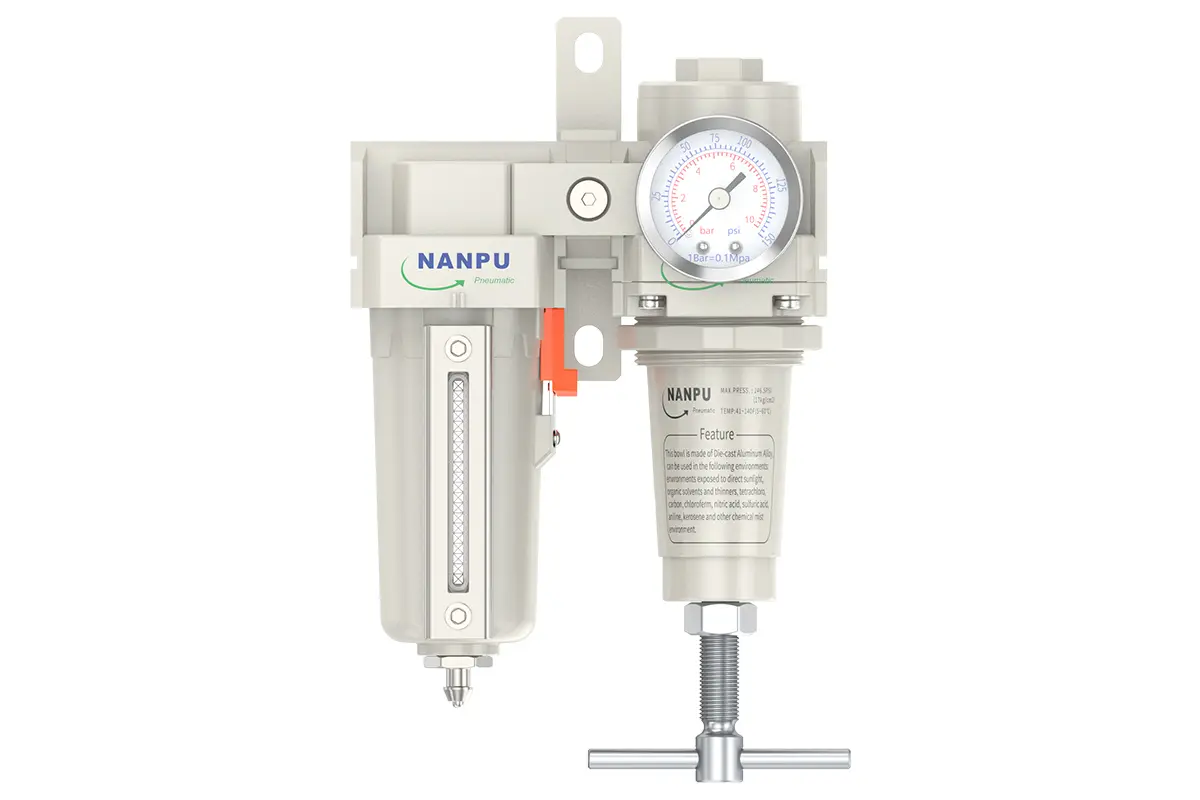

TFR3000-02/03 TFR4000-04/06 3/8" 1/2" 3/4" Air Filter Regulator

description1

TFR3000-02/03 TFR4000-04/06 3/8" 1/2" 3/4" Air Filter Regulator

Manual Drain TFR3000-02/03 TFR4000-04/06 3/8" 1/2" 3/4" Air Filter Regulator

Auto Drain TFR3000-02D/03D TFR4000-04D/06D 3/8" 1/2" 3/4" Air Filter Regulator

NANPUTFR3000-02/03 TFR4000-04/06 3/8" 1/2" 3/4" Air Filter Regulator

| TFR | 3000 | MINI | BSP | D |

| Series Number | Port Size | Thread Type | Drainage Method | |

| 3000 | 02:1/4" 03:3/8" | BSP | Blank: Differential Pressure Drain | |

| 4000 | 04:1/2" 06:3/4" | NPT | A: Manual Drain |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 2.0Mpa{20.39kgf/cm²} 290Psi |

| Max Operating Pressure | 1.8Mpa{18.35kgf/cm²} 261Psi |

| Temperature Range | 5~60℃ |

| Filtration Accuracy | 5μm、40μm |

| Body Material | Aluminium/Zinc |

| Bowl Guard | YES |

| Suggested Oil | Turbine Oil No. 1 ISO-VG32 |

| Pressure Range | TC3000~4000:0.05~1.8Mpa(0.51~18.35kgf) |

| Model | Model | |

| Manual Drain | Auto Drain | (L/min)Rated Flow Rate |

| TFR3000-02 | TFR3000-02D | 2000 |

| TFR3000-03 | TFR3000-03D | 2000 |

| TFR4000-04 | TFR4000-04D | 4000 |

| TFR4000-06 | TFR4000-06D | 4500 |

| Product Benefits |

| All Portsize Piggyback Air Filter (0.01μm、 5μm、40μm) |

| Regulator & Filter air dryer system |

| Temperature Range: 41-140℉ (5-60℃) |

NANPUInstallation and Operating

1.PreparationAll calibration units are required to satisfy the highest flow rate specifications.

Before fitting, clean the ports and connectors thoroughly to effectively prevent debris from getting into the air pipe.

Verify that the direction of airflow matches the arrow markers on the product shell, and make sure the port and thread dimensions are properly aligned.

2. Pressure Adjustment

Lift the pressure gauge dial and begin rotating it. Twisting in a clockwise manner will cause a gradual increase in pressure, whereas turning it counterclockwise will bring about a decrease. Once the desired pressure value is achieved, cease rotating and securely fasten the dial. Failure to properly execute this securing step could lead to potential leakage issues.

3. Dial Reading

5-Micron Brass Filter Cartridge: Boasts outstanding filtering performance, a significantly extended service life, and permits multiple reuses.

0.5 and 0.01-Micron Filter Cartridges: Successfully eliminate minute impurities.

The drainage tube operates independently. It triggers to discharge substances when pressure is absent and closes when air passes through. Once the water level exceeds the preset maximum, immediate draining is required; neglecting this will reduce moisture-removal efficiency.

4.Drainage

The drainage tube is equipped with an auto-activating mechanism. It opens to expel materials when pressure is absent and shuts as soon as air flows through. When the water level goes beyond the stated upper limit, immediate draining is crucial; failing to do so will lead to subpar moisture-removal effectiveness.

The fitting on the drain cap acts as a link for air pipes and can be detached based on specific operational requirements.

Use a properly dimensioned spanner to fasten the fittings to the necessary torque value so as to prevent leakage. During the first installation, an air release incident may occur. This is not a leak; rather, it arises from the pressure disparity between internal and external environments, which demands the discharge of excess air. In such cases, allow the system to stabilize for an adequate period, after which it will operate optimally.