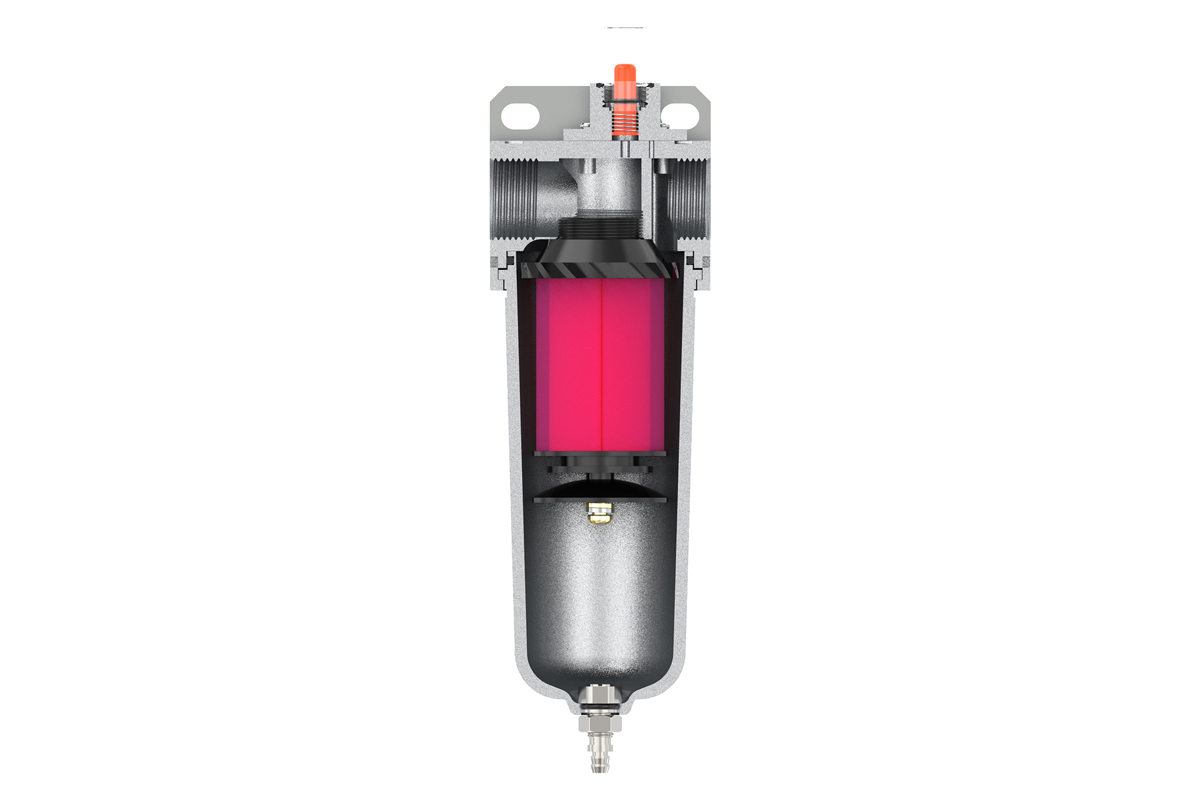

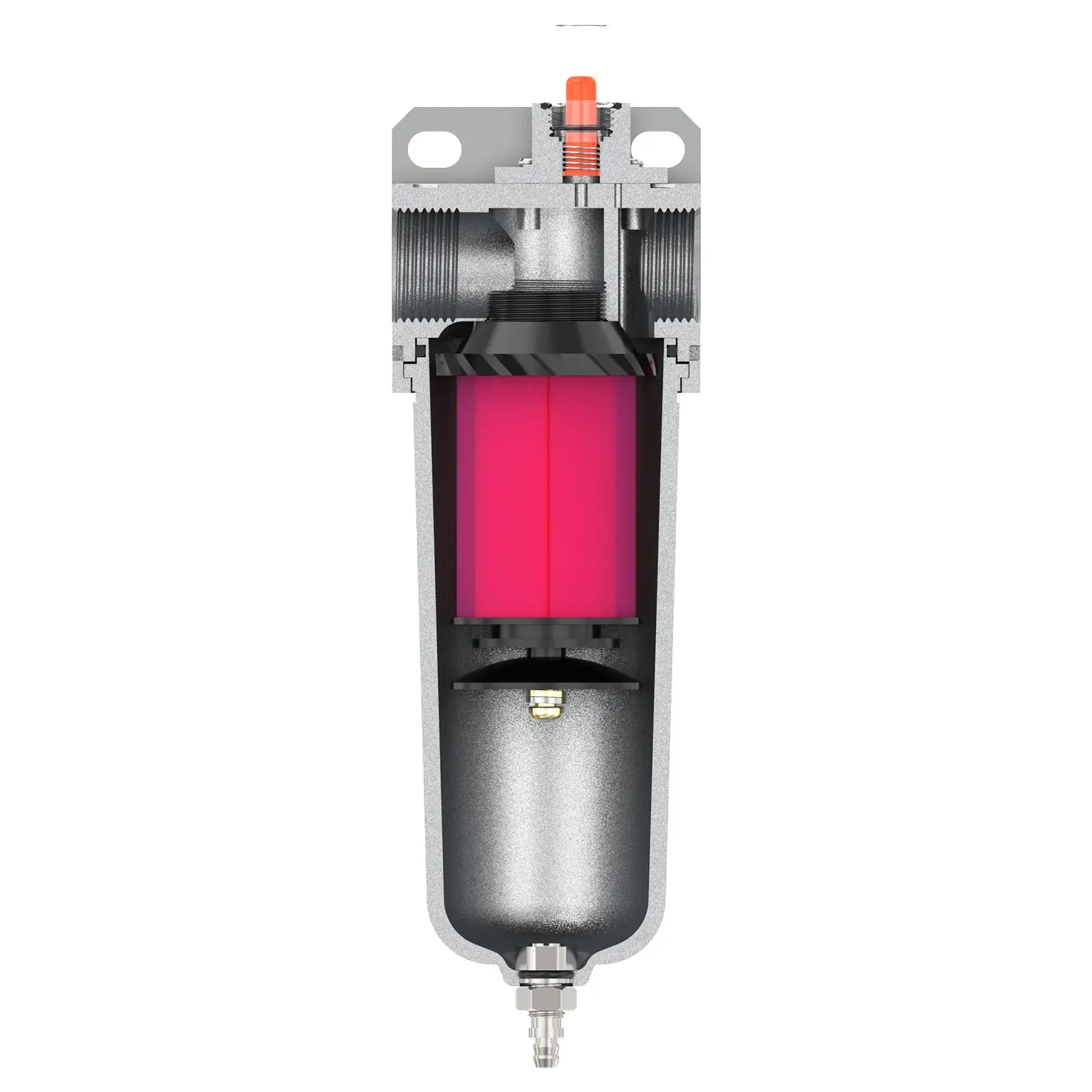

NANPU Ultrafine Particle Filter - FP44 FP46

description1

FP44 1/2", FP46 3/8", Preparation

To attain optimal performance and stringent adherence to industry standards, the assembly of calibration components demands meticulous precision. Each component must be installed in strict compliance with the maximum flow parameters specified in the system design, ensuring unimpeded operation and peak efficiency.

Prior to installation, comprehensive cleaning of all ports and fittings is imperative. Utilize appropriate solvents or compressed air to eliminate particulate contaminants entirely, thereby preventing dust ingress into the airflow path. This proactive measure not only enhances operational efficacy but also extends the service life of downstream equipment.

Furthermore, careful attention must be directed toward proper airflow alignment, which requires rigorous verification against the product’s clearly delineated arrow indicators.

Concurrently, ensure exact conformity of all port and thread dimensions with the system’s specified requirements to preclude leaks and operational anomalies. Strict adherence to these protocols guarantees seamless integration and reliable long-term functionality.

NANPUNANPU Ultrafine Particle Filter - FP44 FP46

| FP | 44 | NPT |

| Series Number | Port Size | Thread Type |

| 44:1/2" | BSP | |

| 46:3/4" | NPT | |

| PT |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.6Mpa{16.32kgf/cm²} 232.06Psi |

| Max Operating Pressure | 1.48Mpa{15.09kgf/cm²} 214.7Psi |

| Temperature Range | -5~60℃ |

| Body Material | Aluminum Alloy |

| Bowl Guard | YES |

| Filtration Accuracy | 0.01μm |

| Model | Specification (L/min)/Rated Flow Rate |

| FP44 | 4000 |

| FP46 | 4000 |

| Product Benefits |

1.NANPU Ultrafine Particle Filter with diverse and comprehensive air treatment functions.

2.It is equipped with a poly bowl, which is helpful for relevant operations in the air treatment process.

3.It has a manual drain function, allowing for on-demand drainage operations, which is convenient and practical.

4.It is of the medium flow type and can meet certain air consumption requirements.

5.It has a wide range of applications, being suitable for paint spray and plasma cutters. With 1/2" 3/4" interface, it has good adaptability.

NANPUManual Drain

Actuate the manual drain valve by smoothly rotating the ergonomic lever to the "↓" position, initiating the immediate and continuous discharge of exhaust and water from the filter cup. This critical procedure must be executed promptly upon the water level reaching the specified maximum mark to ensure sustained dehumidification efficacy. Delayed drainage may result in moisture buildup, posing a risk of damage to interconnected equipment. To terminate the process, simply align the lever with the "↑" indicator—this seals the valve and prevents pressurized leakage. Adhere strictly to the maintenance schedule to avert blockages and preserve the valve's optimal operational performance.

The coalescing filter is outfitted with a highly visible service indicator, functioning as a dependable signal for filter element replacement. This intuitive mechanism is engineered to notify users precisely when the filter reaches the termination of its effective service life. Upon the indicator's activation, immediate replacement of the filter element is imperative. Prompt replacement sustains the filtration system's efficiency and protects downstream equipment from potential damage arising from degraded filtering performance.

The NANPU Air Drying System boasts an extensive application landscape. Within automotive manufacturing, it secures contaminant-free air for spray-painting procedures, precluding particle-induced imperfections on automotive surfaces. Electronics production lines leverage it to protect sensitive components from moisture and airborne particulates during assembly. In the food and beverage sector, it sustains a dry, contaminant-free air supply for packaging apparatuses. Even in aerospace—where precision is critical—this system functions to maintain optimal conditions for diverse pneumatic tools and equipment. Its superior air-purification capacities render it a preferred selection across these varied industries.