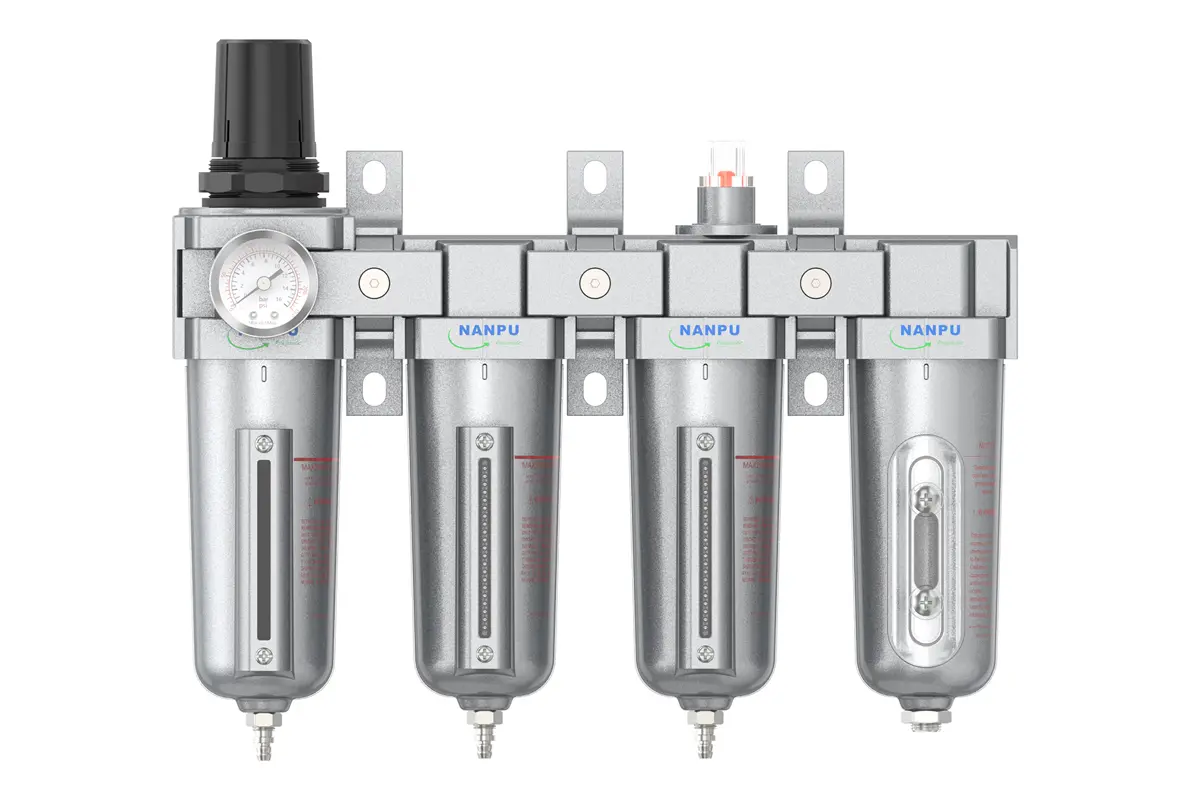

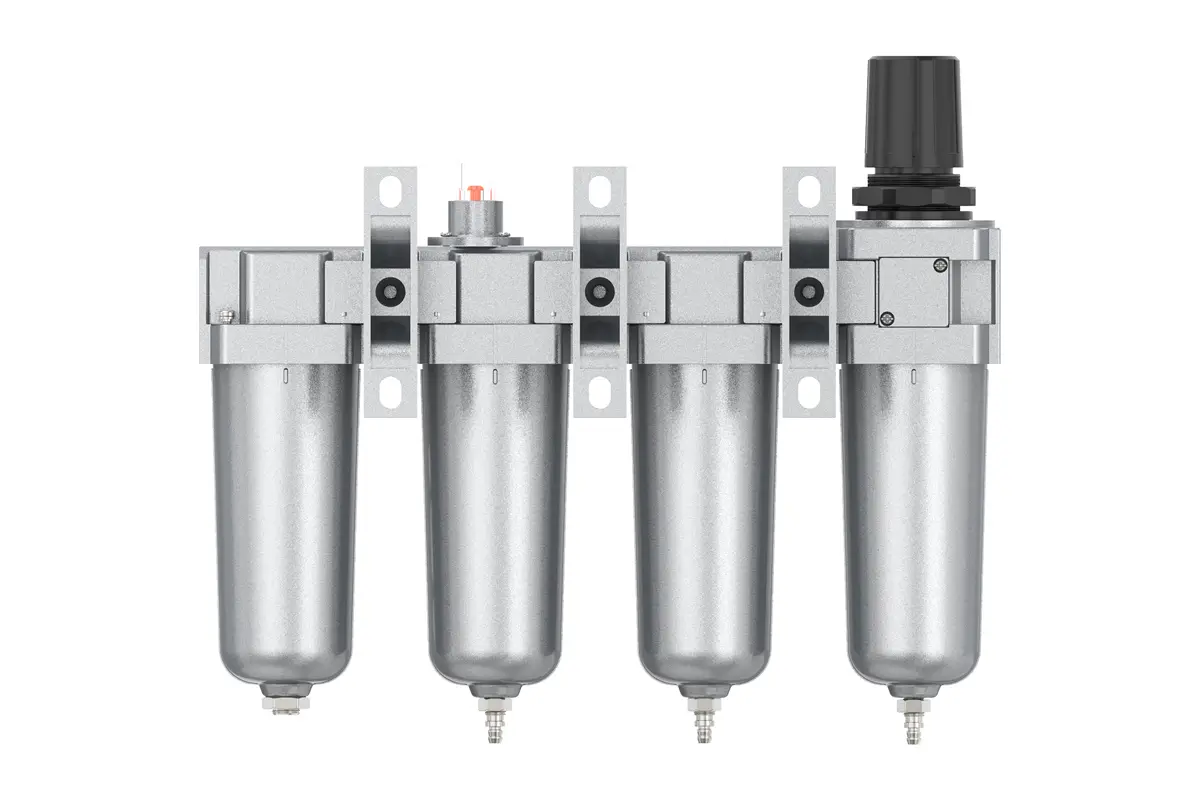

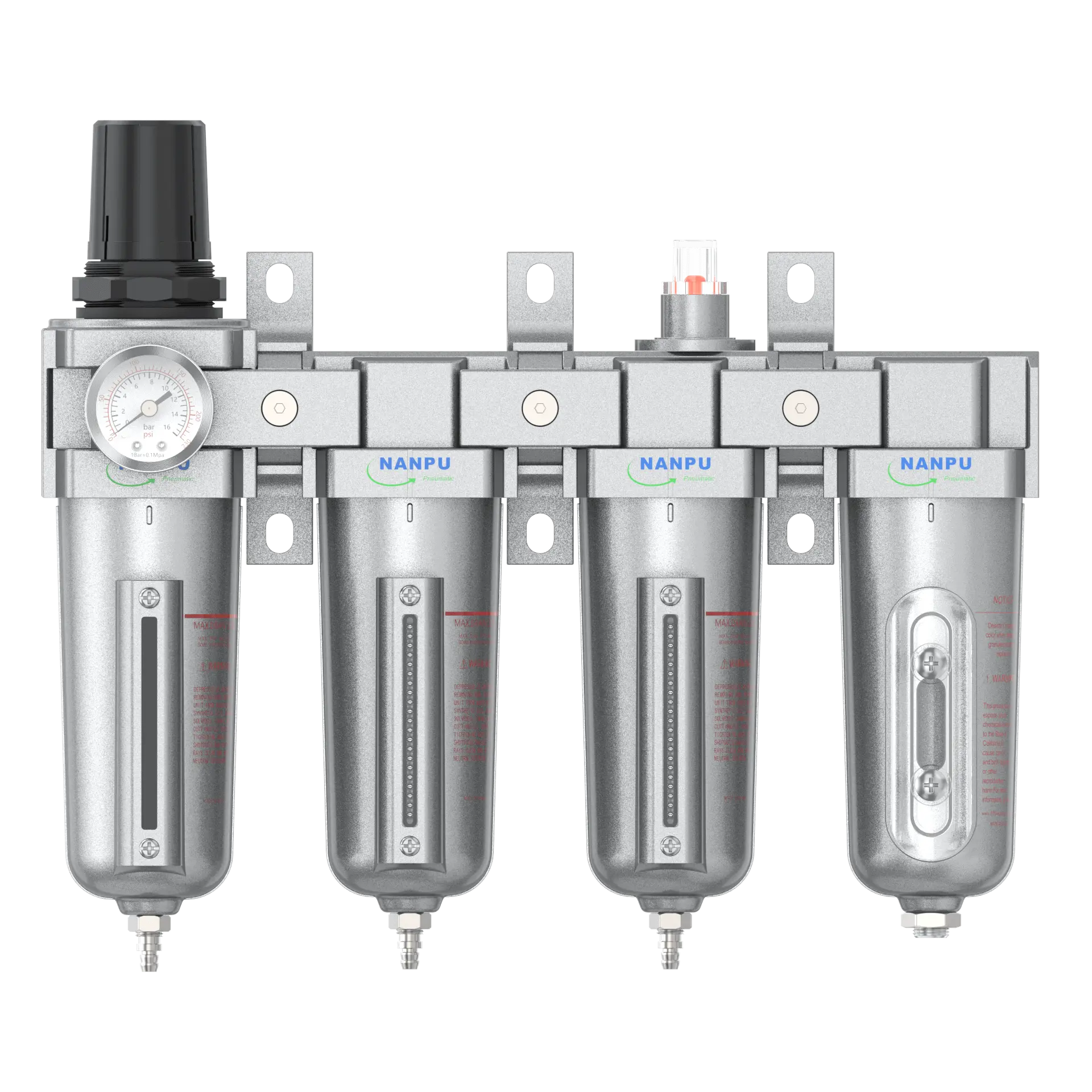

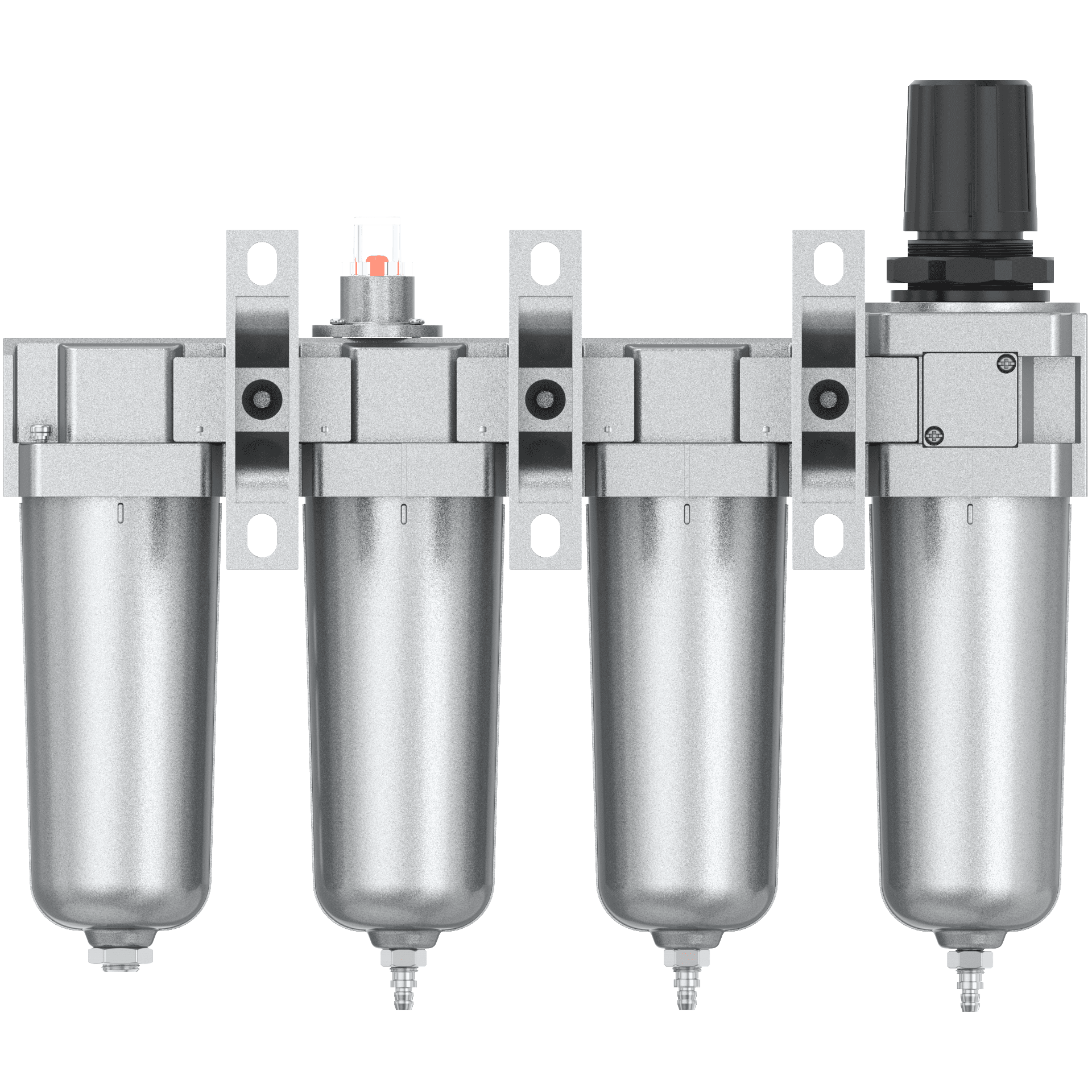

NANPU Industrial-Grade 4-Stage Air Drying System

description1

FRPD-F44/FRPD-F46/FRPD-F46/FRPD-F46D

NANPU 1/2" 3/4" NPT Industrial Grade 4 Stage Air Drying System - Particulate Filter, Coalescing Filter, Desiccant Dryer & Air Regulator, Metal Bowl, Auto Drain, Suitable for Paint Spray& Plasma Cutter

High Pressure Endurance: Operates optimally under a pressure scope of 30-175 psi; Flow Capacity: 141 CFM (4000 L/min) Elevated Safety Standard: A premium metal bowl integrated with a visible sight glass at each stage guarantees safeguarding for both operators and the system during the entire procedure.

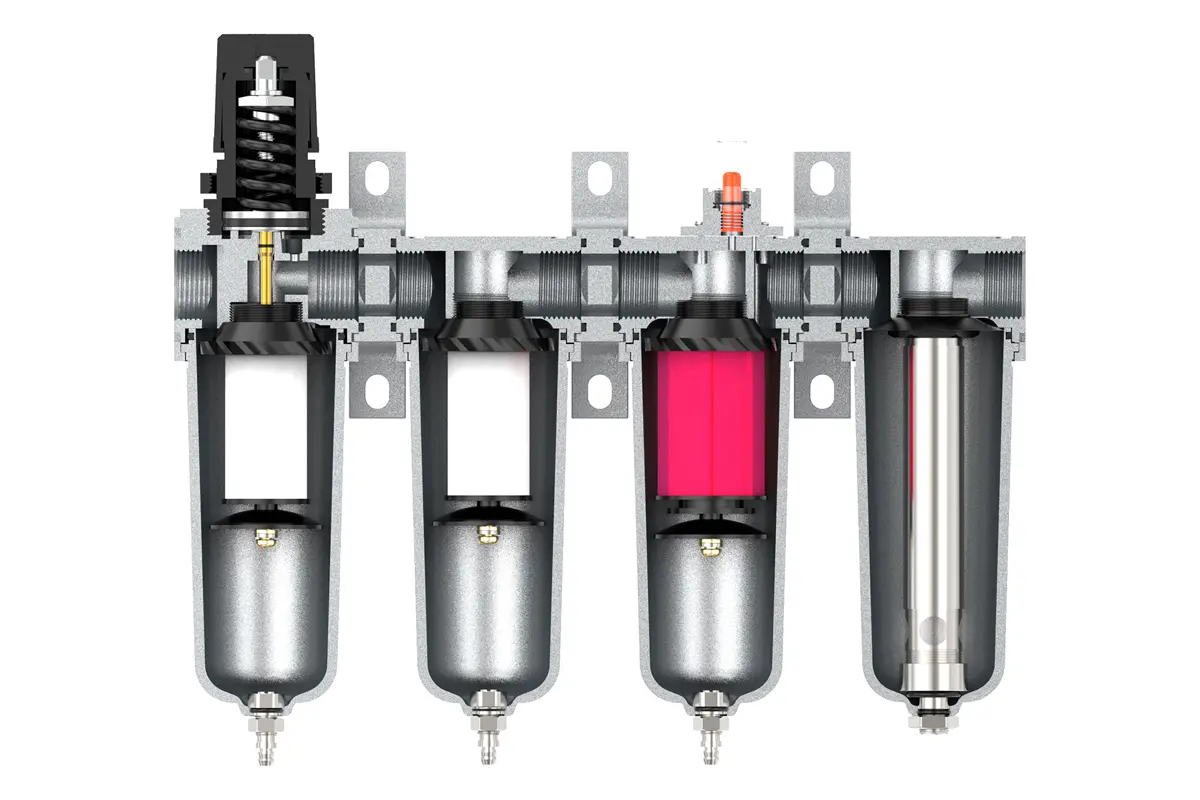

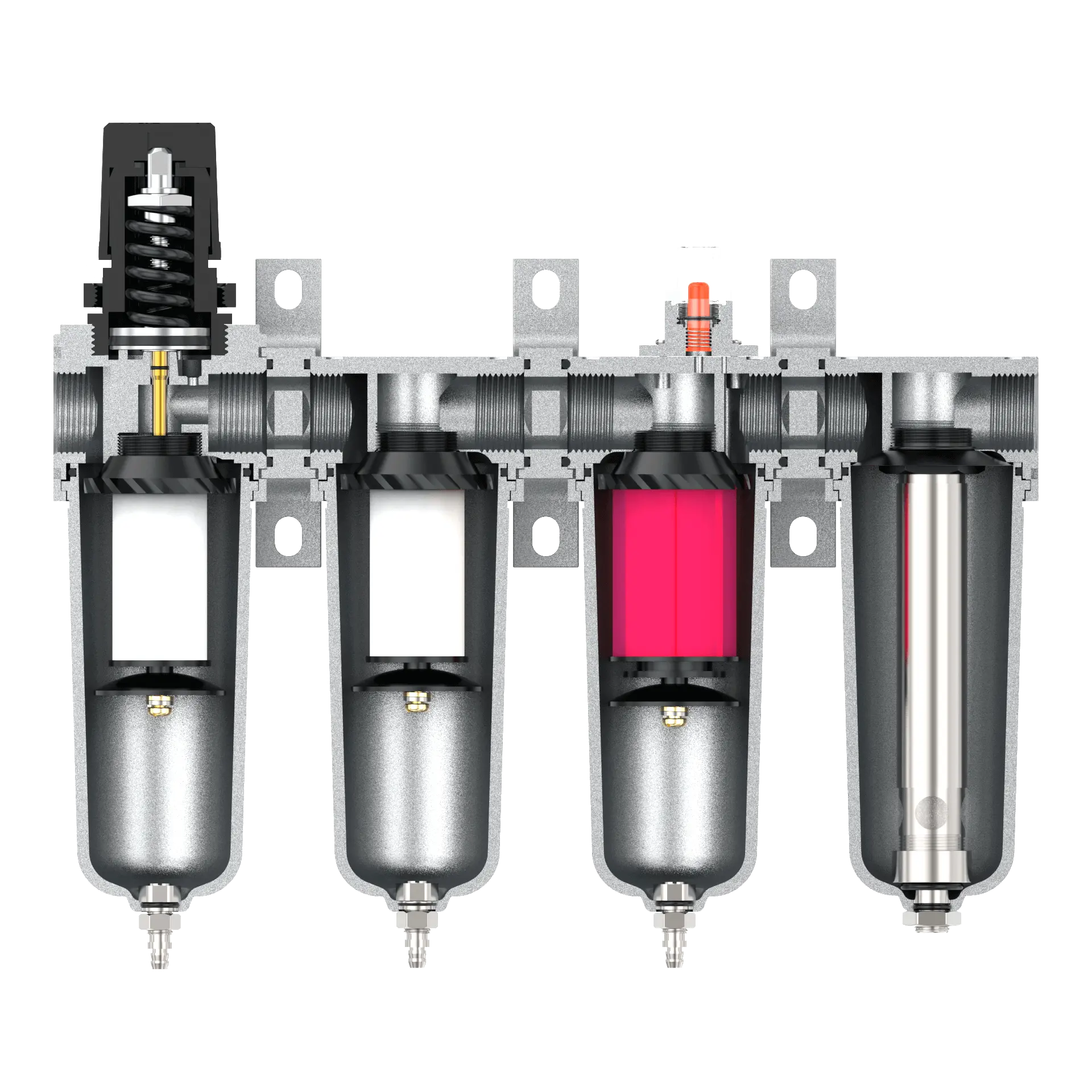

Stage 1: Filtration & Regulation Unit: The compressed air water separator filter is furnished with a 5-micron element, featuring outstanding filtration efficacy, prolonged service duration, and reusability. It eliminates the majority of moisture and particles in the air pipeline; the pressure regulator accurately adjusts and stabilizes air pressure.

Stage 2: Coalescing Filtration Device: Fitted with a 0.01-micron element, this filter removes 99.9% of moisture, fine particles, and oil that traverse the Stage 1 combination unit. A red indicator will project when the filter element needs replacement.

Stage 3: Desiccant Air Drying Unit: This dryer thoroughly dehumidifies and purifies air before it enters pneumatic tools. Desiccant beads must be added to the metal bowl, and they will shift from blue to pink when replacement is required.

NANPUFRPD4 Series 4 Stage Air Drying System FRPD-F44/FRPD-F46

| FRPD | F44: | D | NPT |

| Series Number | F44: 1/2" Filter | Drainage Method | Thread Type |

| F46: 3/4" Filter | Blank: Differential Pressure Drain | BSP | |

| A: Manual Drain | NPT | ||

| D: Auto Drain | PT |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.6Mpa{16.32kgf/cm²} 232.06Psi |

| Max Operating Pressure | 1.48Mpa{15.09kgf/cm²} 214.7Psi |

| Temperature Range | -5~60℃ |

| Filtration Accuracy | 0.01μm、 5μm、40μm |

| Bowl Material | Aluminum Alloy |

| Bowl Guard | FRPD-44~46( |

| Filter bead material | Desiccant |

| Pressure Range | FRPD-44~46:0.05~14.8Mpa(0.51~15.0kgf) |

| Model | Model | Specification | ||

| Manual Drain | Auto Drain | (L/min)/Rated Flow Rate | ||

| FRPD-F44 | FRPD-F44D | 4000 | ||

| FRPD-F46 | FRPD-F46D | 4000 | ||

【High Pressure Resistance】Works Perfectly in the Pressure Environment of 7-215 psi; 【High Degree of Safety】Excellent Metal Bowl w/ Visible Sight Glass in Every Stage Protect You and the System throughout the Entire Process.

【Stage 1: Filter & Regulator】Compressed Air Water Trap Filter Equipped with 5 Micron Element, which has Excellent Filtering Performance, Much Longer Life and Reuse Feasibility, Remove Most of Moisture and Particles in the Air Line; Pressure Regulator Accurately Adjust and Stabilize the Air Pressure.

【Stage 2: Coalescing Filter】The Coalescing Filter is Equipped with a 0.01 Micron Element that can Remove 99.9% of Moisture, Smaller Particles and Oil, which Pass Through Stage 1 Combo. When the Filter Element needs to be Replaced, the Red Indicator will Pop Up.

【Stage 3: Desiccant Air Dryer】The Desiccant Air Dryer allows the Air to be Thoroughly Dried and Cleaned before it Enters your Pneumatic Tools. The Desiccant Beads need to be Added to the Metal Bowl. When it needs to be Replaced, the Beads will Change from Blue to Pink.

| Product Benefits |

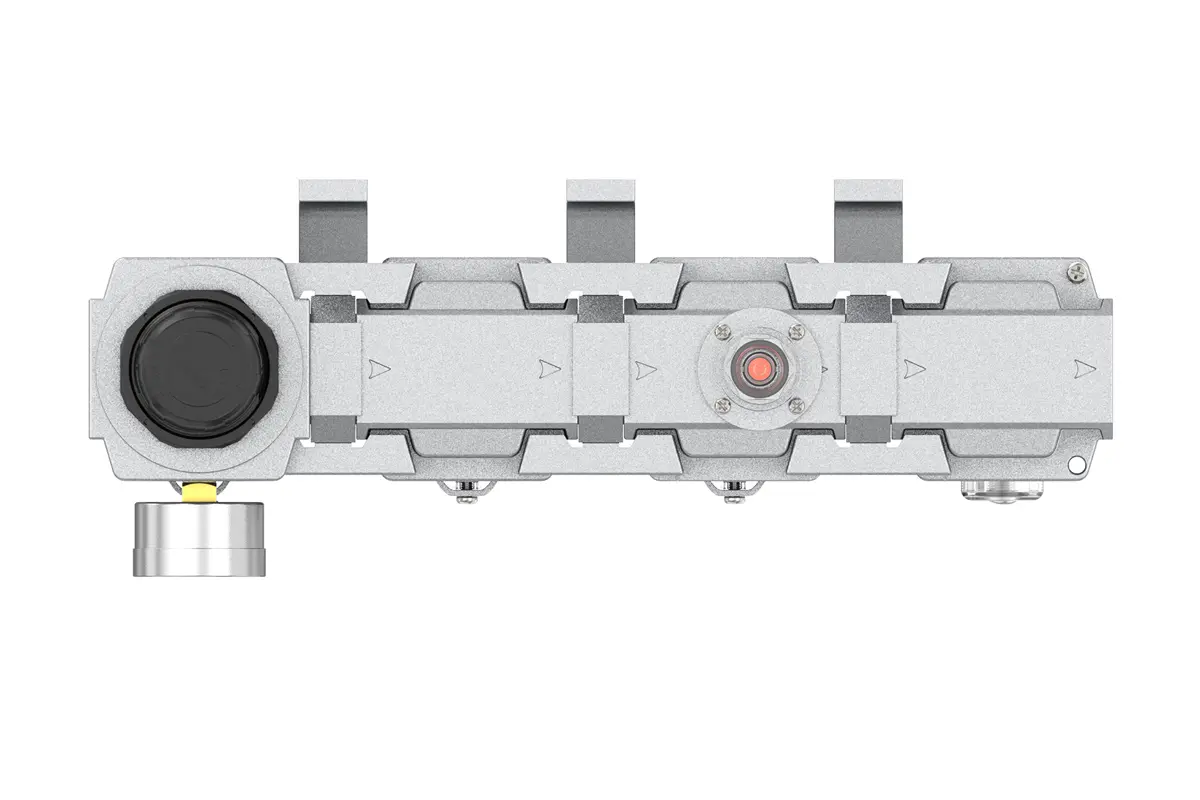

NANPU Preparation and Pressure Adjustment

1.All calibration modules must meet peak flow specifications.

Before fitting, ports and connectors should be cleared to efficiently block dust entry into the air path.

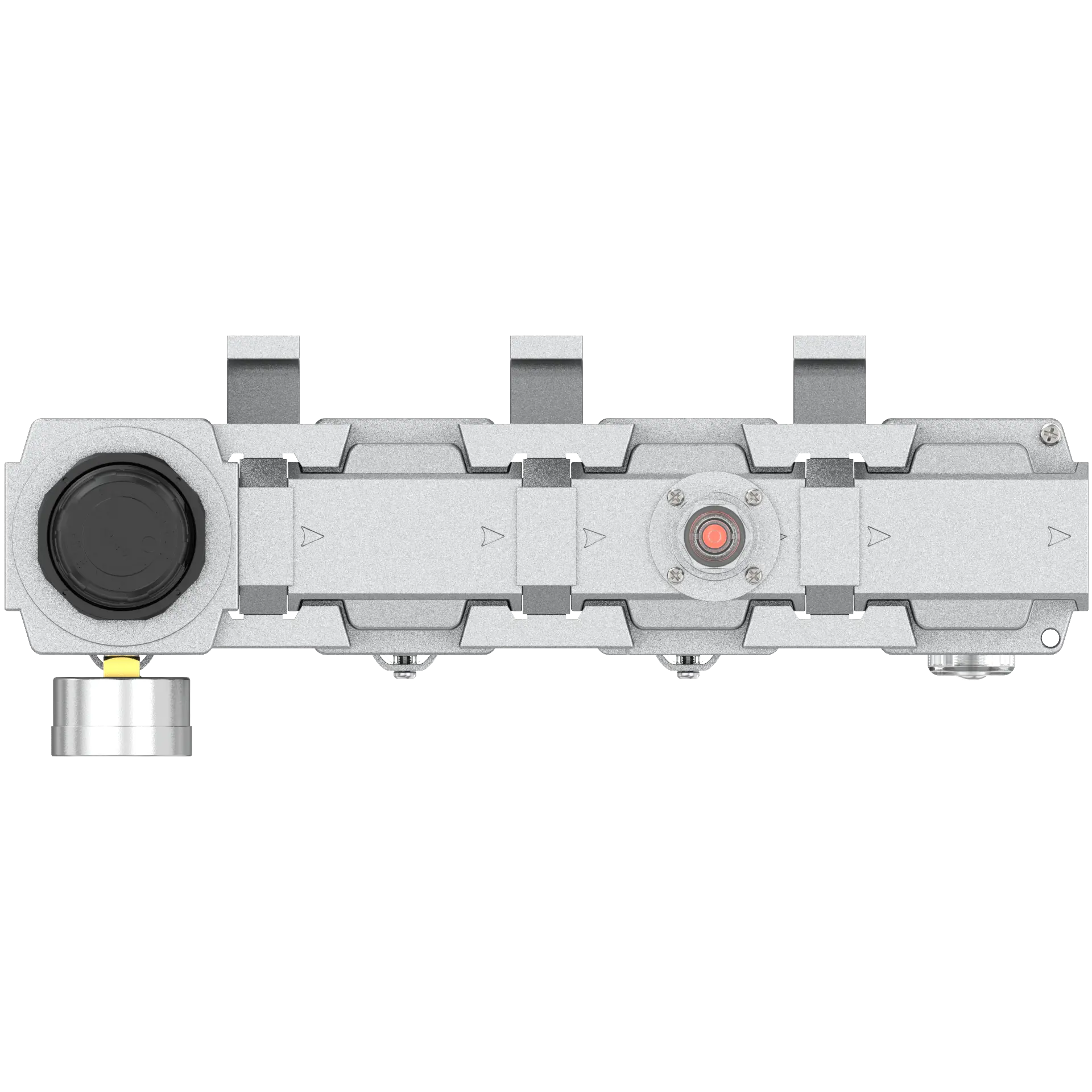

Confirm alignment between airflow orientation and the directional arrow on the product casing, and check conformity of port and thread sizes.

2. Lift the pressure gauge knob and turn it:

A clockwise turn will make the pressure climb steadily; a counterclockwise turn will bring about pressure decrease.

Stop turning when the target reading is achieved and secure the knob—neglect of this step might cause leakage.

3. Gauge Reading

Confirm the pressure gauge is firmly affixed to the main body, and check if the reading varies smoothly during pressure regulation.

4.Auto & Manual Drainage

Automatic Mode: When condensate in the filter housing reaches a specific fill level, the condensate discharge valve opens automatically, expelling condensate via the drain hose into a collection vessel (not supplied) until only a small residual quantity remains. Manual Mode: When water surpasses the designated level, drain it promptly to sustain optimal dehumidification performance. Press the base of the brass drain body to commence drainage

5.The maintenance indicator on the coalescing filter signals when the filter element needs replacement.

Once the indicator extends, the element must be replaced without delay.

6. The initial filtration stage segregates particles exceeding 5μm, together with condensed water and oil.

The secondary filter exhibits a fineness of 0.01μm and a separation efficiency of 99.998% for particles larger than 0.01μm.

The tertiary desiccant dryer, outfitted with desiccant beads, completes the ultimate air purification procedure.