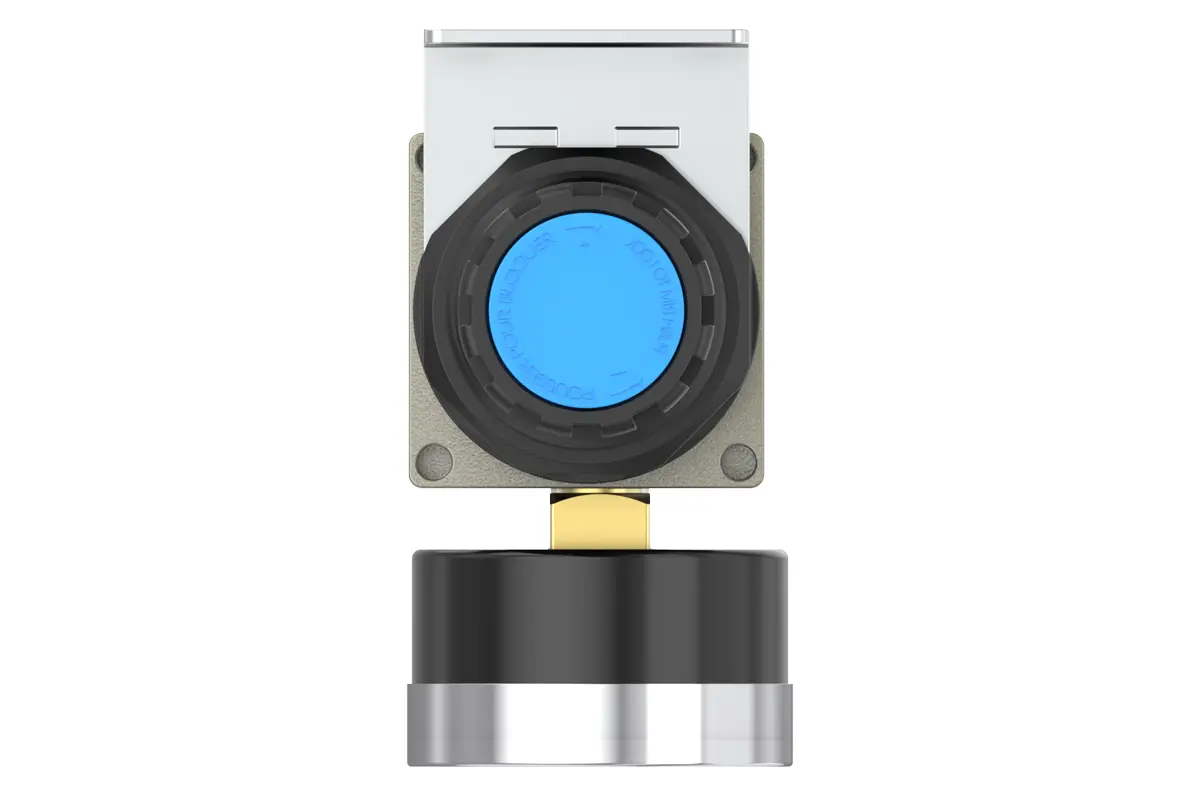

MAR200-08A 1/4" AR Air Regulator

description1

R200 1/4" AR Air Regulator (Zinc Alloy)

R200 1/4" AR Air Regulator (Zinc Alloy)

NANPU R200 1/4" AR Air Regulator (Zinc Alloy)

| R | 200 | 02 | BSP |

| Series Number | Body Size | Port Size | Thread Type |

| R200 | 200 | 01:1/8“ | |

| 02:1/4” |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | 5~60℃ |

| Pressure Range | (0.51~8.7kgf/cm² )/0~125Psi |

| Model | Specification |

| R200 | 500 |

| Product Benefits |

| The assembly of all calibration shall meet the maximum flow requirement. Please clean the port and fitting before installation, it will effectively avoid bring dust to the air path. Pay attention to direction of air flow and arrow pointing on product body if correct, minding port and thread size if match. |

NANPUPreparation

All calibration assemblies shall strictly comply with the maximum flow rate requirements specified in the technical documentation. Such compliance is vital to ensuring the optimal performance and reliability of the system.

Prior to installation, it is imperative to meticulously clean all ports and fittings by means of appropriate cleaning agents and protocols. This thorough cleaning process effectively prevents dust, debris and other contaminants from entering the air path, thus upholding the integrity and efficiency of the compressed air system.

During installation, careful attention must be paid to verifying that the air flow direction is in precise alignment with the arrow markings on the product body. Furthermore, it is essential to ensure that the port and thread sizes are accurately compatible with the corresponding components. This meticulous verification of dimensions and flow direction is indispensable to avoiding potential installation errors that may result in system malfunctions or inefficiencies.

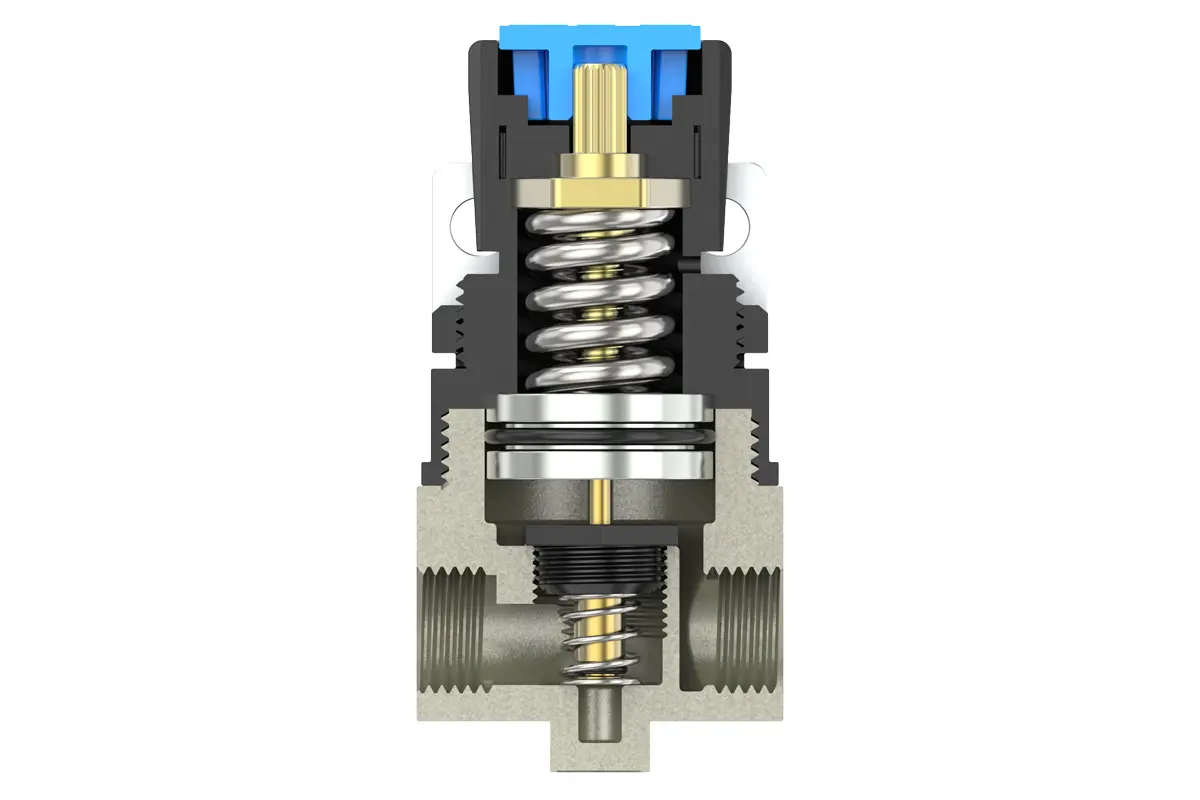

To adjust the pressure, first, lift the pressure gauge knob to the unlocked position. Subsequently, rotate the knob to modify the pressure settings. A clockwise rotation will yield a gradual and consistent pressure increase, while a counterclockwise rotation will trigger a steady pressure decrease.

It is crucial to closely monitor the pressure gauge and terminate rotation once the desired pressure index is attained. After reaching the required pressure level, firmly lock the knob to secure the setting. Improper locking of the knob may result in seal failure, potentially inducing leakage issues that could impair the system's performance and safety. During operation, conduct regular checks on the locked knob to ensure the pressure remains stable and within the specified range.

Ensure that the pressure gauge is securely and correctly mounted on the main body by utilizing appropriate installation tools and methodologies, while adhering to the specified torque requirements to preclude potential leakage or displacement. During the pressure adjustment process, closely monitor the pressure gauge to confirm that the readings increase and decrease in a smooth, consistent manner, free from erratic fluctuations or jamming. Any abnormal behavior in the gauge readings may indicate issues such as internal blockages, damaged components, or improper calibration—these circumstances shall be promptly investigated and resolved to maintain the accuracy and reliability of the pressure monitoring system.