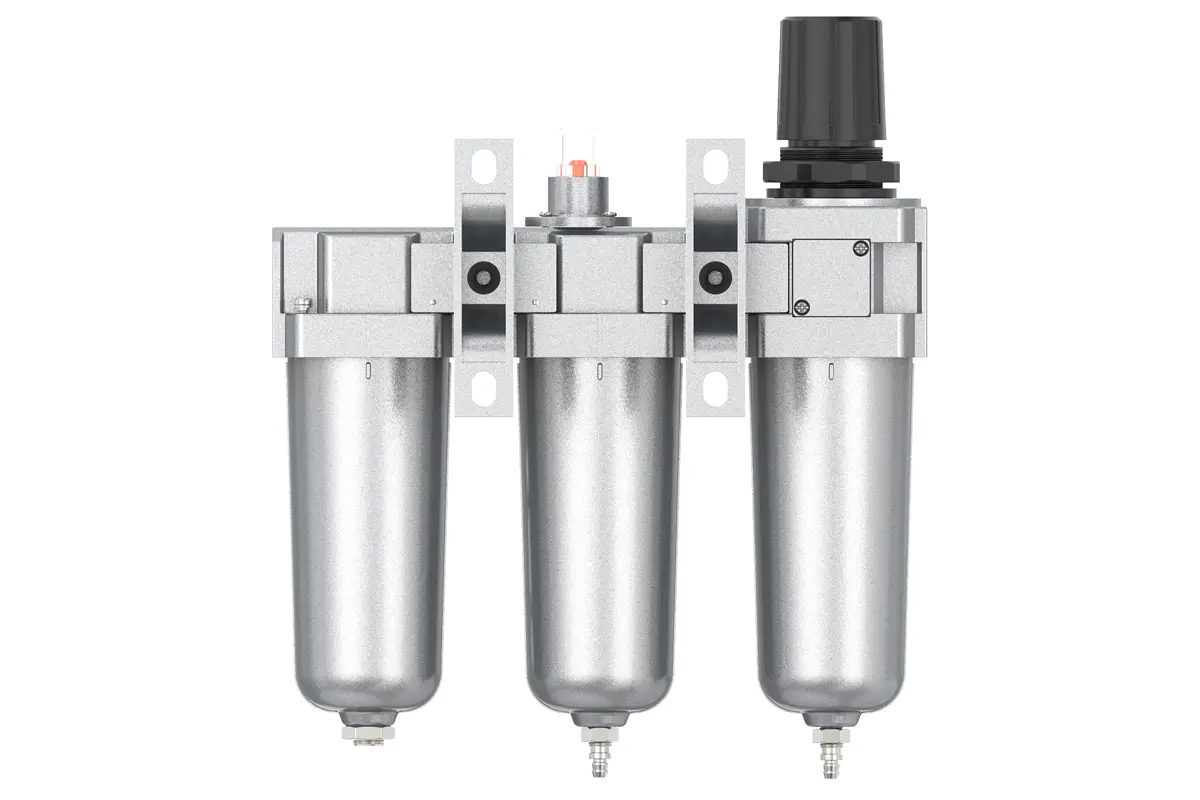

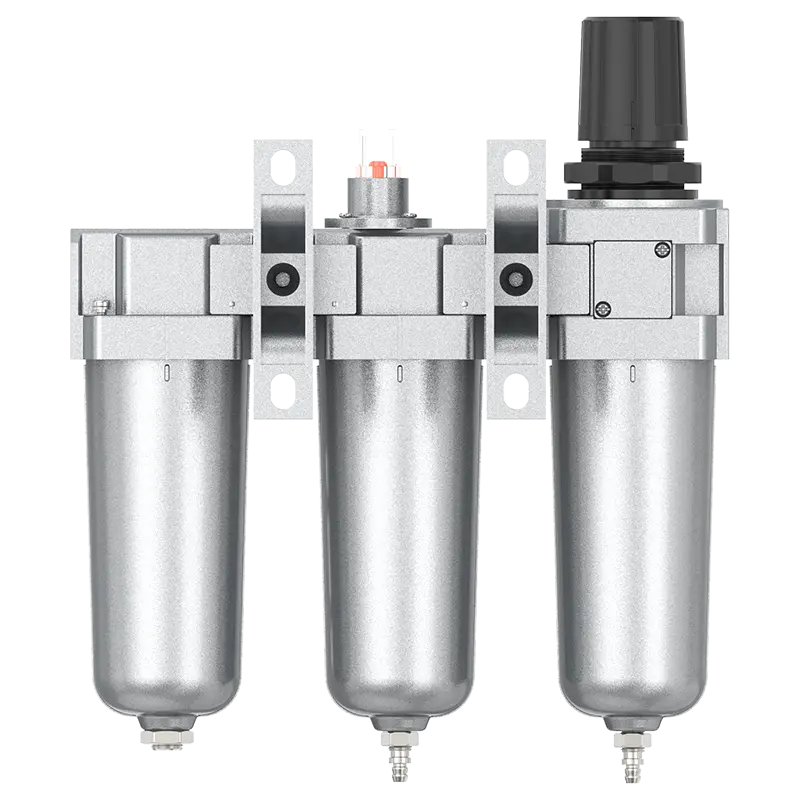

FRPD4 Series 3 Stage Air Drying System

description1

FRPD44/FRPD46/FRPD44D/FRPD46D

NANPU 3/4" NPT Industrial Grade 3 Stage Air Drying System - Particulate Filter, Coalescing Filter, Desiccant Dryer & Air Regulator, Metal Bowl, Auto Drain, Suitable for Paint Spray& Plasma Cutter

NANPUFRPD4 Series 3 Stage Air Drying System

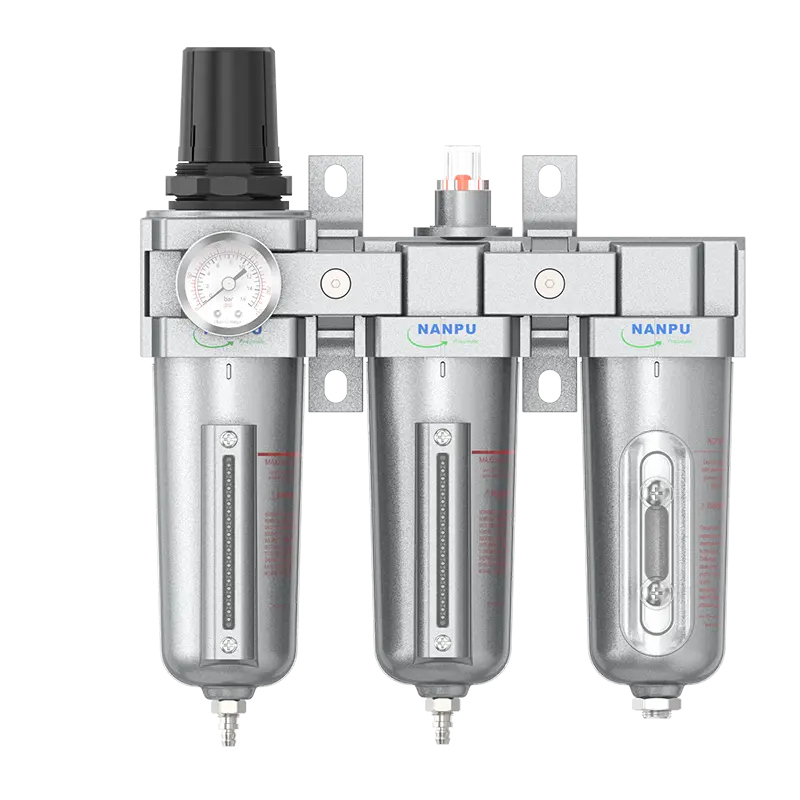

| FRPD | 44 | NPT | D |

| Series Number | Port Size | Thread Type | Drainage Method |

| 04:1/2 | BSP | Blank: Differential Pressure Drain | |

| 06: 3/4 | NPT | A: Manual Drain | |

| PT | D: Auto Drain |

NANPUTechnical Specifications

| Technical Specifications | |

| Max Input Pressure | 1.6Mpa{16.32kgf/cm²} 232.06Psi |

| Max Operating Pressure | 1.48Mpa{15.09kgf/cm²} 214.7Psi |

| Temperature Range | -5~60℃ |

| Filtration Accuracy | 0.01μm、 5μm、40μm |

| Bowl Material | Aluminum Alloy |

| Bowl Guard | FRPD-44~46( |

| Filter bead material | Desiccant |

| Pressure Range | FRPD-44~46:0.05~14.8Mpa(0.51~15.0kgf) |

| Model | Model | Specification | |

| Manual Drain | Auto Drain | (L/min)/Rated Flow Rate | |

| FRPD44 | FRPD44D | 4000 | |

| FRPD46 | FRPD46D | 4000 | |

| Product Benefits | |||

| High Pressure Resistance】Works Perfectly in the Pressure Environment of 7-215 psi; 【High Degree of Safety】Excellent Metal Bowl w/ Visible Sight Glass in Every Stage Protect You and the System throughout the Entire Process. | |||

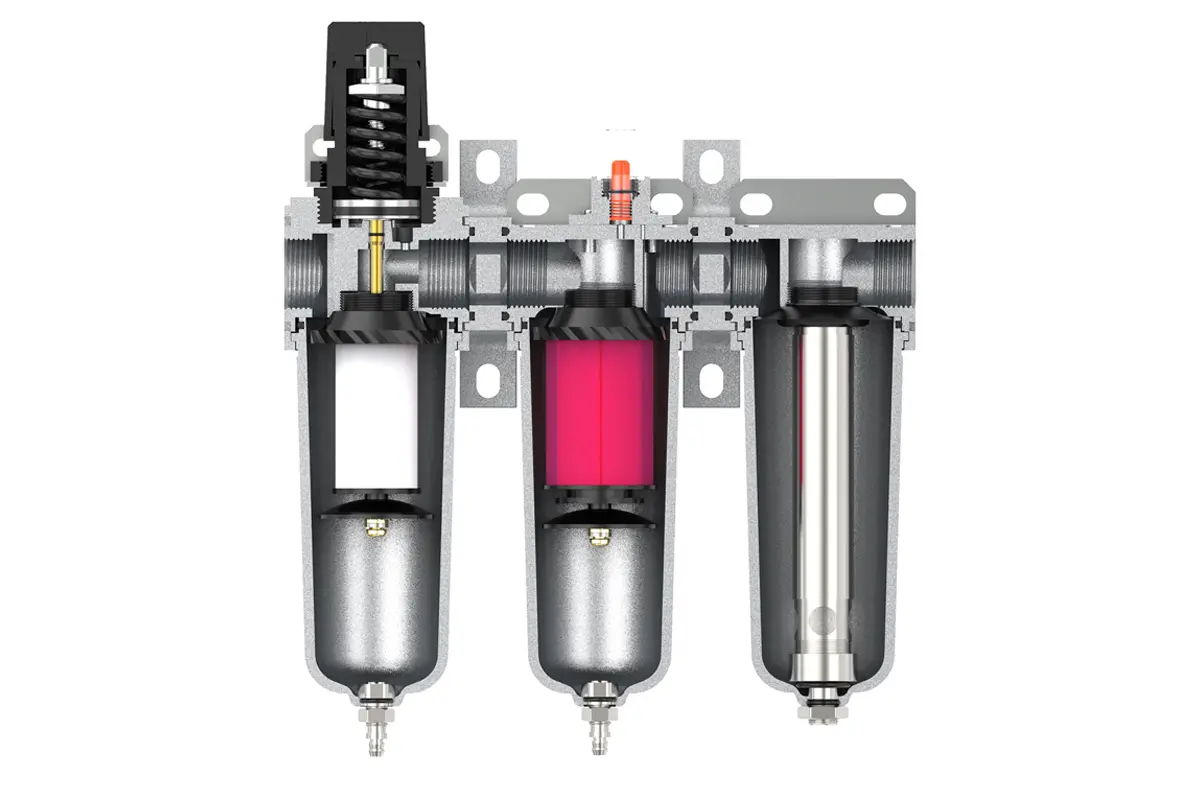

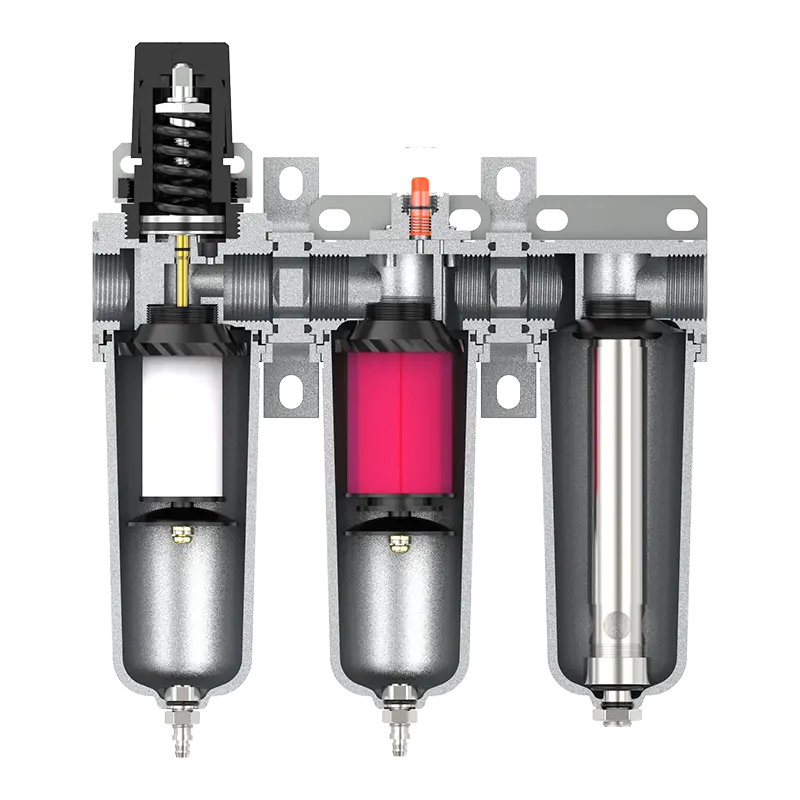

| 【Stage 1: Filter & Regulator】Compressed Air Water Trap Filter Equipped with 5 Micron Element, which has Excellent Filtering Performance, Much Longer Life and Reuse Feasibility, Remove Most of Moisture and Particles in the Air Line; Pressure Regulator Accurately Adjust and Stabilize the Air Pressure. | |||

| 【Stage 2: Coalescing Filter】The Coalescing Filter is Equipped with a 0.01 Micron Element that can Remove 99.9% of Moisture, Smaller Particles and Oil, which Pass Through Stage 1 Combo. When the Filter Element needs to be Replaced, the Red Indicator will Pop Up. | |||

| 【Stage 3: Desiccant Air Dryer】The Desiccant Air Dryer allows the Air to be Thoroughly Dried and Cleaned before it Enters your Pneumatic Tools. The Desiccant Beads need to be Added to the Metal Bowl. When it needs to be Replaced, the Beads will Change from Blue to Pink. | |||

NANPU Preparation and Pressure Adjustment

3.Dial Reading

Make sure that the pressure gauge is tightly installed on the main body, and pay attention to whether the reading rises and falls smoothly while adjusting pressure.

4.Auto & Manual Drain

Auto: If a certain condensate filling level is reached inside the filter housing the condensate drain valve opens automatically draining the condensate through the condensate drain hose into the collection container( not included in delivery) until just a small residual quantity remains.

Manual: When water exceeds the level, please drain off the water to keep optimal dehumidification. Press up the bottom of the brass drain body, then it will start to drain.

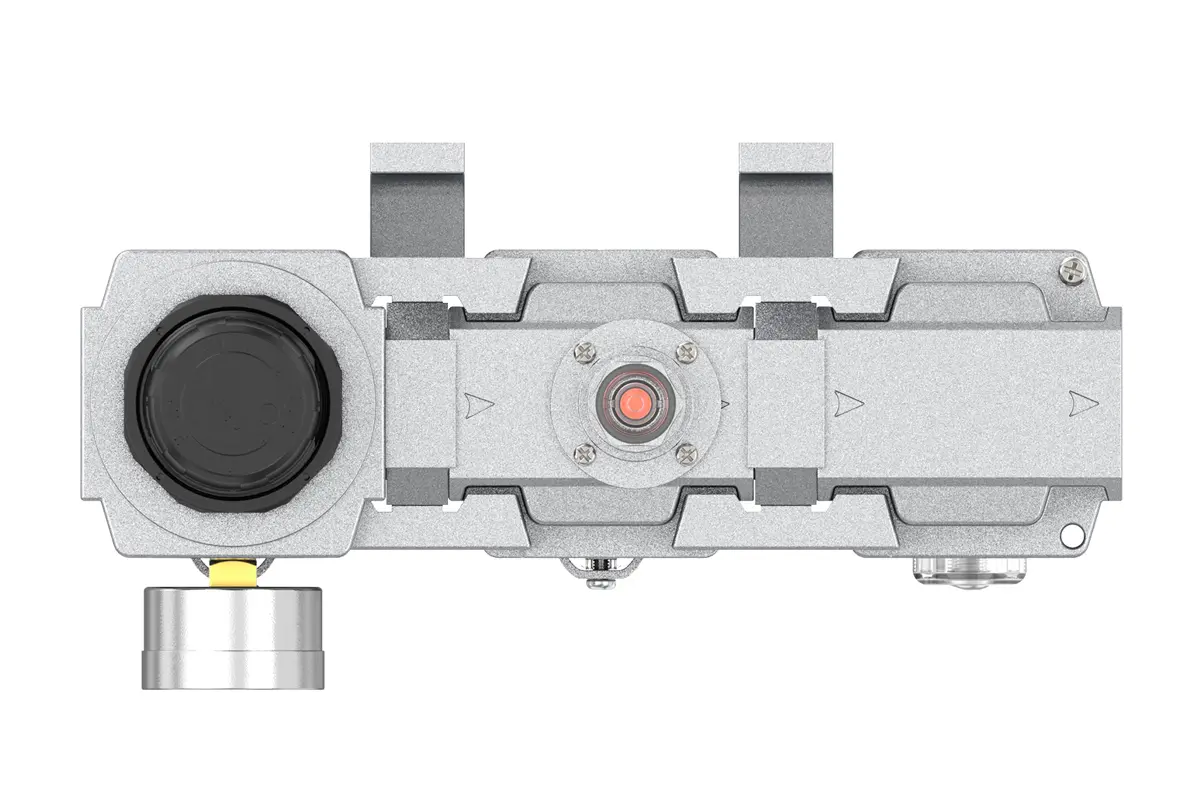

5.The service indicator on the coalescing filter signals when the filter element needs to be replaced.

When the indicator pops up, the element must be replaced.

6.1:The first filter stage separates particles > 5μm as well as condensed water and oil.

2:The second filter fineness 0.01μm, separation degree 99.998% related to a particle size > 0.01μ.

3:The third stage desiccant dryer with desiccant beads completes the final air cleaning work.