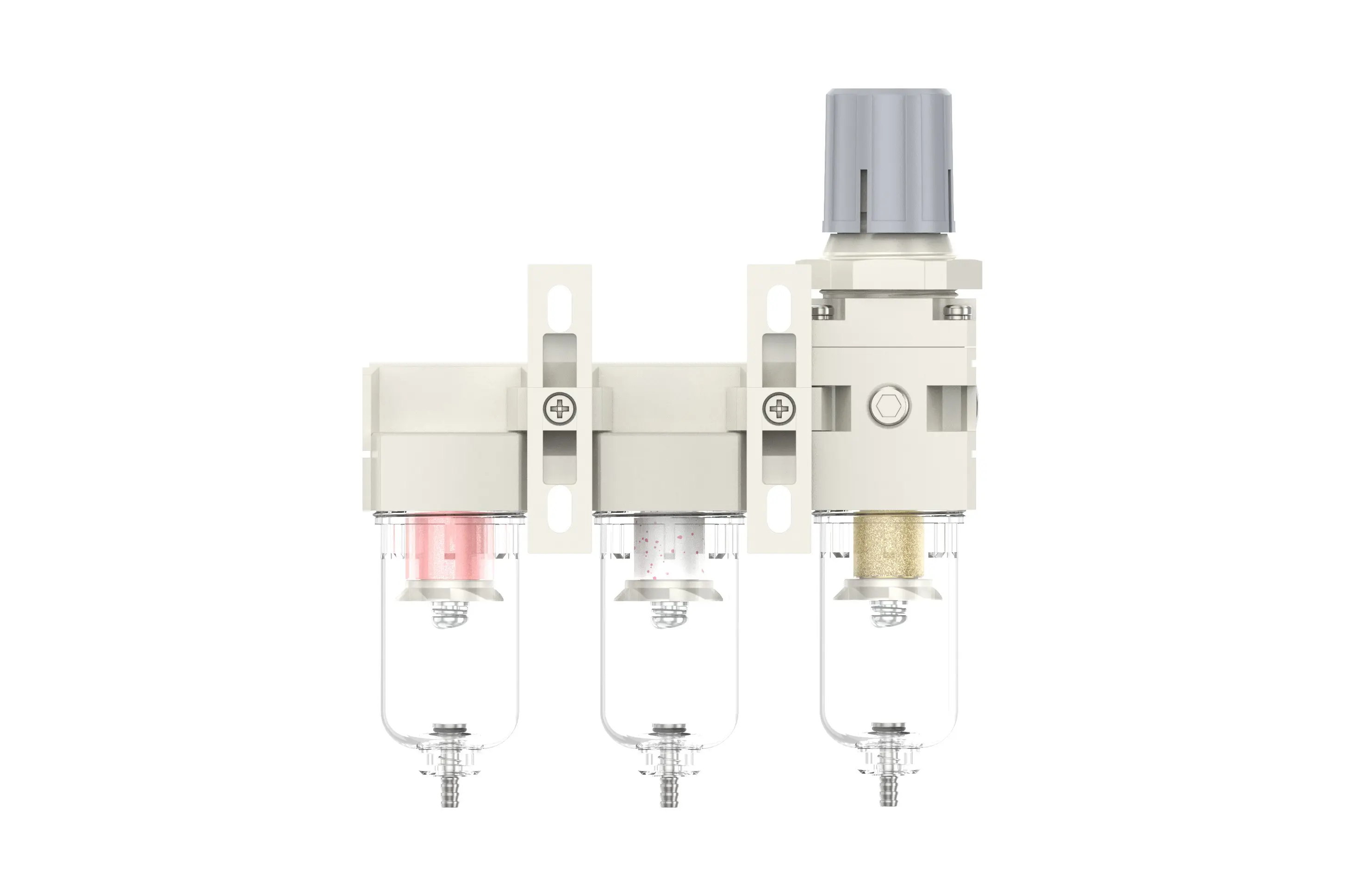

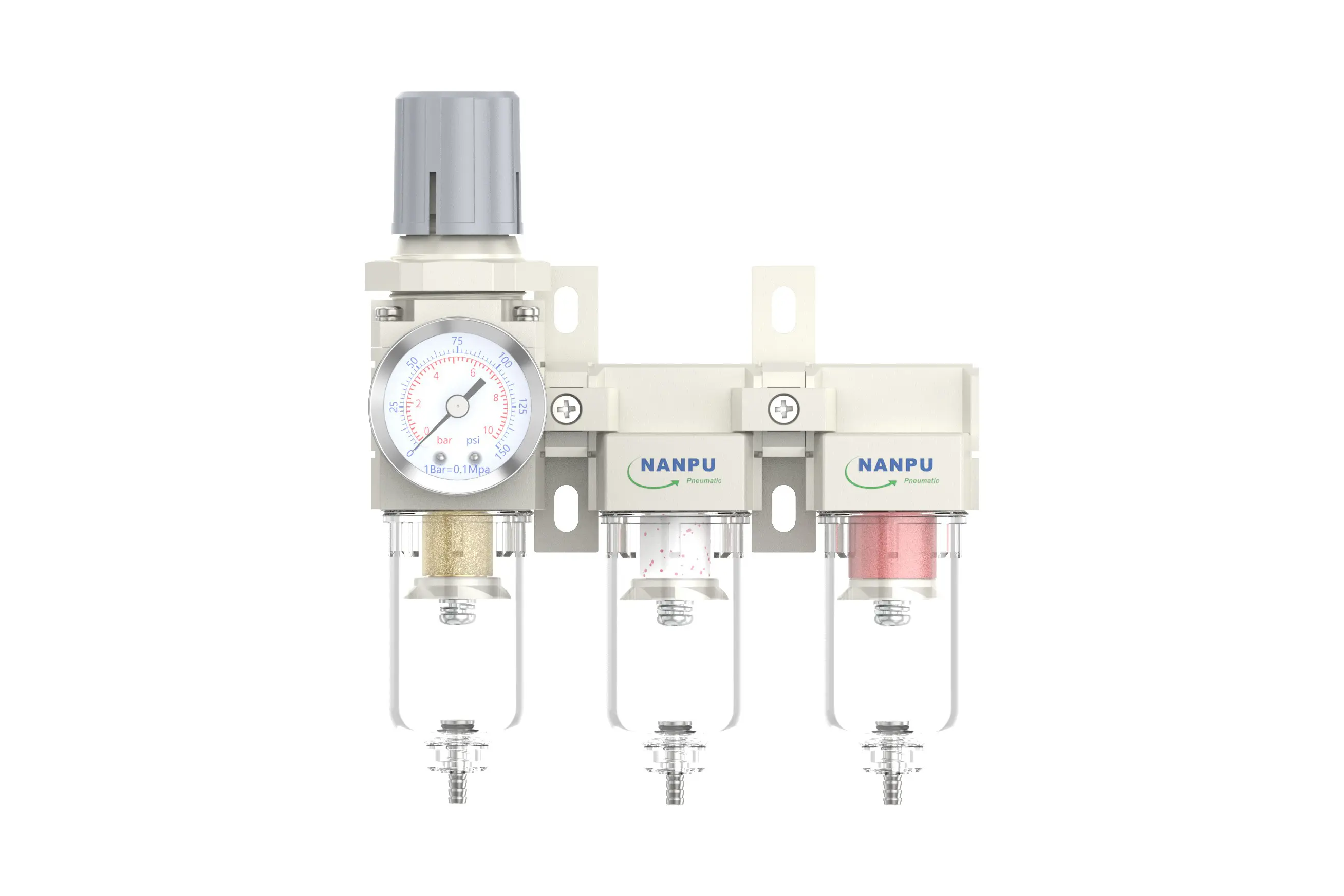

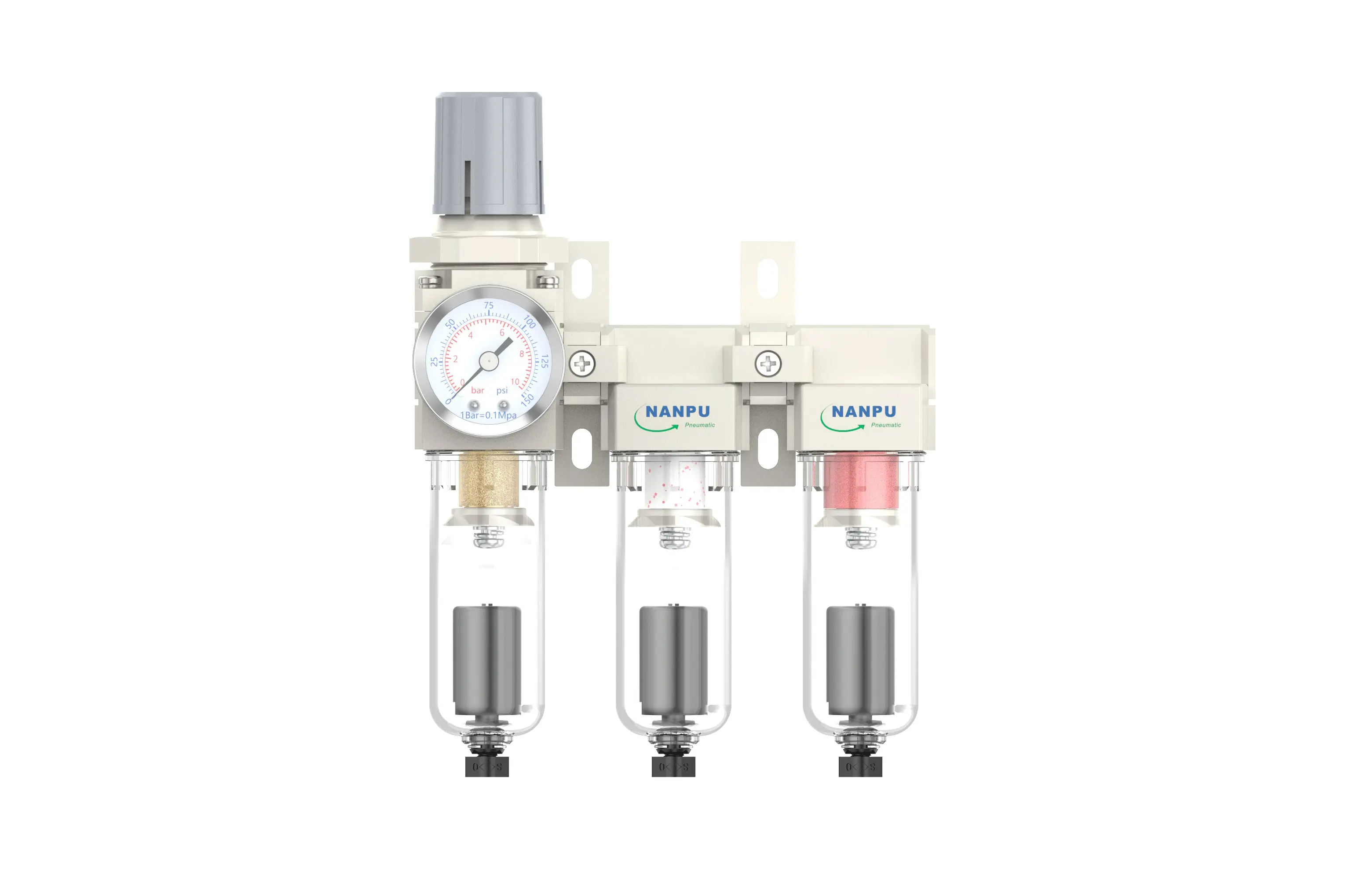

AWFF2010-02/AWFF2010-02D 1/4" AWFF Air Drying System

description1

AWFF2010-02/AWFF2010-02D

Manual Drain AWFF2010-02 Portsize:1/4" Air Drying System

Auto Drain AWFF2010-02D Portsize:1/4" Air Drying System

NANPUAWFF2010-02/AWFF2010-02D

| AWFF | 2010 | 02 | BSP | D |

| Series Number | Body Size | Port Size | Thread Type | Drainage Method |

| 2000 | 02:1/4" | BSP | Blank: Differential Pressure Drain | |

| 3000 | 03:3/8" | NPT | A: Manual Drain | |

| 4000 | 04:1/2" | PT | D: Auto Drain | |

| 4000/5000 | 06: 3/4" | |||

| 5000 | 10: 1" |

NANPUTechnical Specifications

| Model | Model | |

| Manual Drain | Auto Drain | (L/min)Rated Flow Rate |

| AWFF2010-02 | AWFF2010-02D | 500 |

| AWFF3010-02 | AWFF3010-02D | 2000 |

| AWFF3010-03 | AWFF3010-03D | 2000 |

| AWFF4010-04 | AWFF4010-04D | 4000 |

| AWFF4010-06 | AWFF4010-06D | 4500 |

| AWFF5010-06 | AWFF5010-06D | 5000 |

| AWFF5010-10 | AWFF5010-10D | 5000 |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | 5~60℃ |

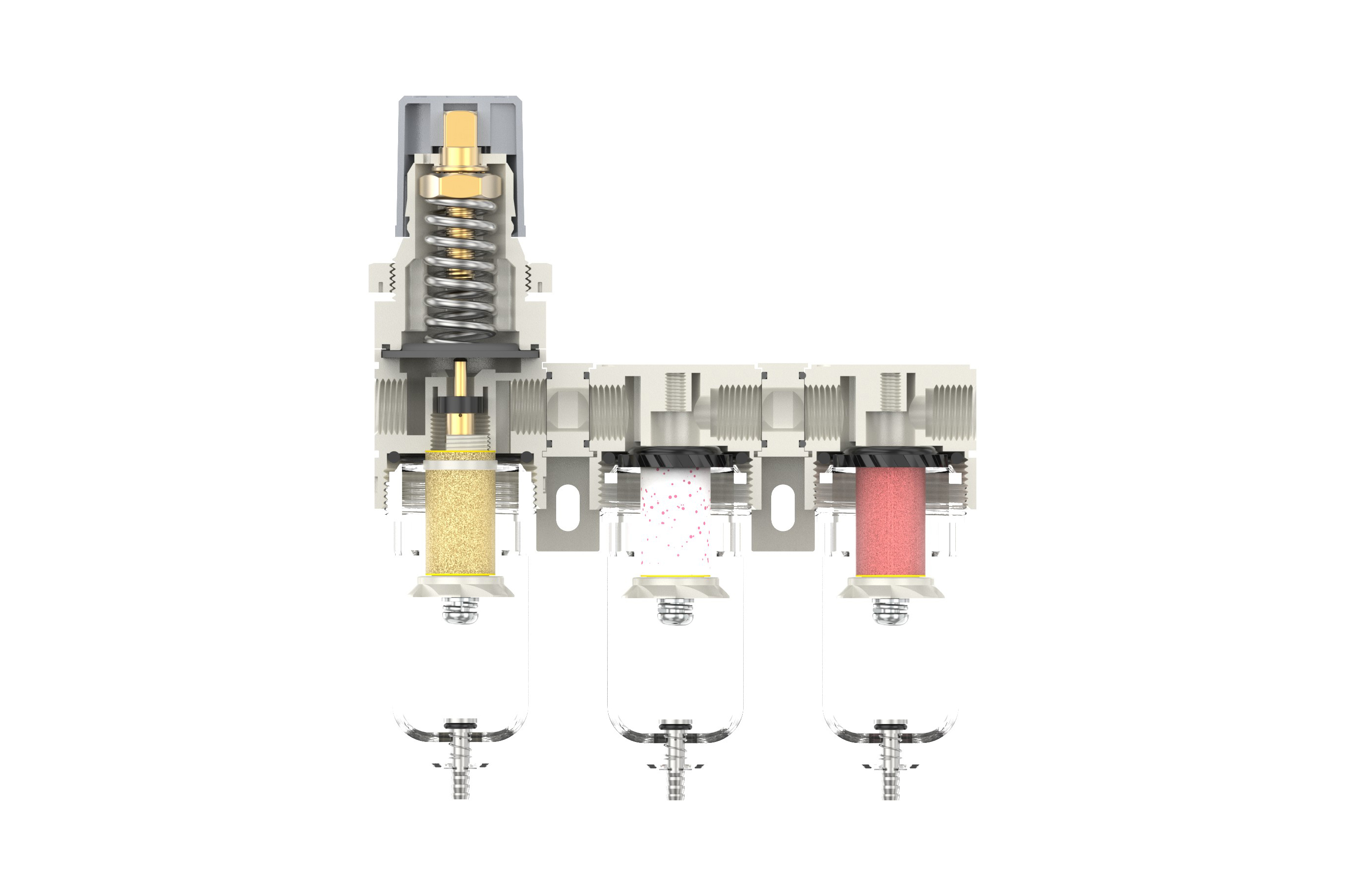

| Filtration Accuracy | 0.01μm, 5μm, 40μm |

| Bowl Material | Polycarbonate |

| Bowl Guard | AC2000(None) AC3000~5000(YES) |

| Pressure Range | AC2000~5000/0.05~0.85Mpa(0.51~8.7kgf/cm² )/0~125Psi |

1. Preparation

All calibration components must be assembled in a manner that satisfies the maximum flow capacity specifications. Prior to installation, it is mandatory to thoroughly clean all ports and fittings. This critical preparatory step serves to prevent the introduction of particulate matter into the air passageway, thereby maintaining the integrity and optimal performance of the system.

2. Pressure Adjustment

To adjust the pressure, first, lift the knob of the pressure gauge. Then, initiate rotation: a clockwise rotation will result in a gradual and consistent increase in pressure, while a counterclockwise rotation will cause a corresponding decrease. Once the desired pressure reading is achieved, immediately cease rotation and securely lock the knob in place. Failure to perform this locking step can lead to pressure leakage, potentially compromising system performance and safety.

3. Dial Reading

The 5 - micron brass filter element demonstrates superior filtration capabilities, offering an extended service life and the potential for reuse. This design not only ensures efficient particle removal but also contributes to cost - effectiveness and sustainability.

The 0.5 - micron and 0.01 - micron filter elements are engineered to perform highly precise filtration, effectively eliminating minute impurities that could otherwise compromise system functionality.

The drainage column is equipped with a self - regulating mechanism. In the absence of pressure, it automatically initiates the drainage process, and seals shut upon the passage of air flow. Should the water level exceed the designated threshold, immediate drainage is required to maintain optimal dehumidification performance; failure to do so will result in reduced efficiency and potential system degradation.

4. Drainage

The drainage column incorporates a self - actuating mechanism. In the absence of pressure, it automatically initiates the expulsion of accumulated fluids, while sealing shut upon the passage of airflow. When the water level reaches or surpasses the maximum allowable limit, immediate drainage is required to maintain optimal dehumidification performance. Failure to do so may lead to reduced efficiency and potential system malfunctions.

The connector on the drain head is designed for coupling with an air hose. It offers the flexibility to be detached or reattached as per operational requirements, facilitating easy customization and maintenance of the system setup.

It is recommended to utilize a wrench for the proper tightening of fittings to ensure a secure connection and prevent any potential leakage. During the initial installation, an expulsion phenomenon may occur. This is not indicative of a leakage issue; rather, it is a result of the pressure differential between the internal system and the external environment, necessitating the release of excess air. In such instances, it is advisable to allow sufficient time for the system to equalize. This patience will enable the system to achieve optimal functionality and performance.