AW2000-02/AW2000-02D AW Filter Regulator

description1

AW2000-02/AW2000-02D AW Filter Regulator

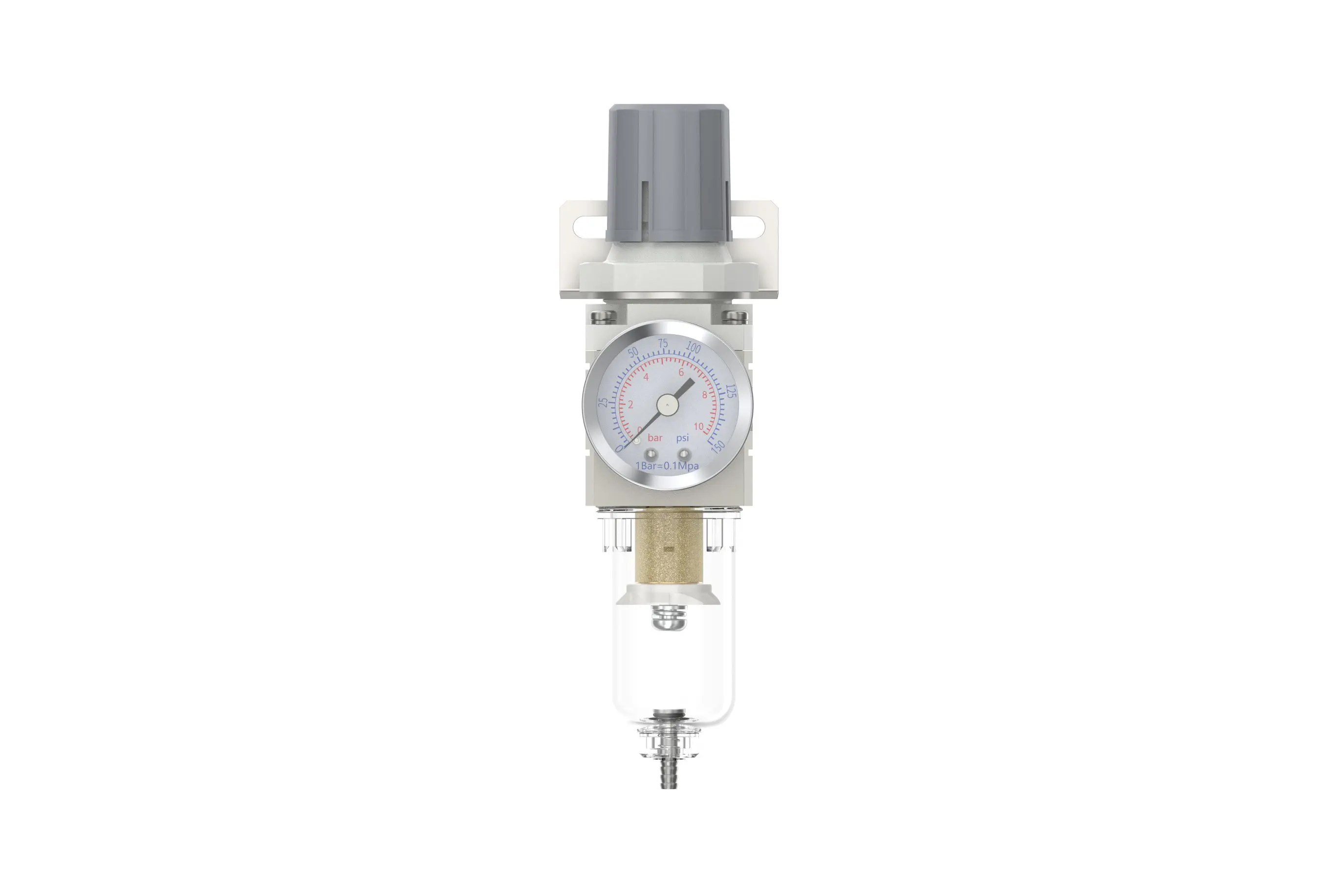

Manual Drain AW2000-02 Portsize:1/4" AW Filter Regulator

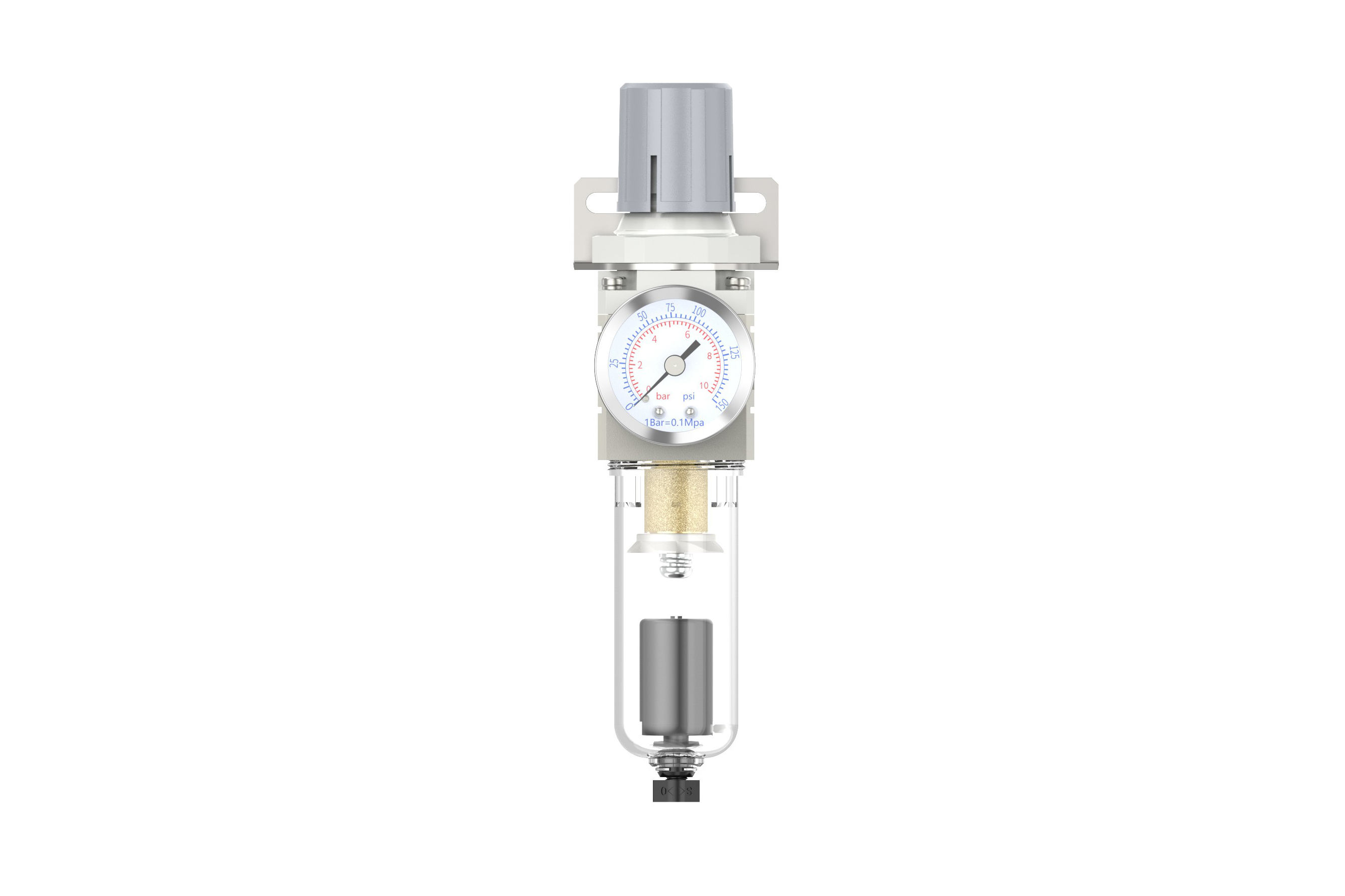

Auto Drain AW2000-02D Portsize:1/4" AW Filter Regulator

NANPUAW2000-02/AW2000-02D AW Filter Regulator

| AW | 2000 | 02 | BSP | D |

| Series Number | Body Size | Port Size | Thread Type | Drainage Method |

| 2000 | 02:1/4" | BSP | Blank: Differential Pressure Drain | |

| 3000 | 03:3/8" | NPT | A: Manual Drain | |

| 4000 | 04:1/2" | PT | D: Auto Drain | |

| 4000/5000 | 06: 3/4" | |||

| 5000 | 10: 1" |

NANPUTechnical Specifications

| Model | Model | |

| Manual Drain | Auto Drain | (L/min)Rated Flow Rate |

| AW2000-02 | AW2000-02D | 500 |

| AW3000-02 | AW3000-02D | 2000 |

| AW3000-03 | AW3000-03D | 2000 |

| AW4000-04 | AW4000-04D | 4000 |

| AW4000-06 | AW4000-06D | 4500 |

| AW5000-06 | AW5000-06D | 5000 |

| AW5000-10 | AW5000-10D | 5000 |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | 5~60℃ |

| Filtration Accuracy | 0.01μm, 5μm, 40μm |

| Bowl Material | Polycarbonate |

| Bowl Guard | AC2000(None) AC3000~5000(YES) |

| Pressure Range | AC2000~5000/0.05~0.85Mpa (0.51~8.7kgf/cm² )/0~125Psi |

1. Preparation

Every calibration assembly must comply with the specified maximum flow capacity.

Before installation, meticulously cleanse the ports and connectors to efficiently stop debris from infiltrating the air system.

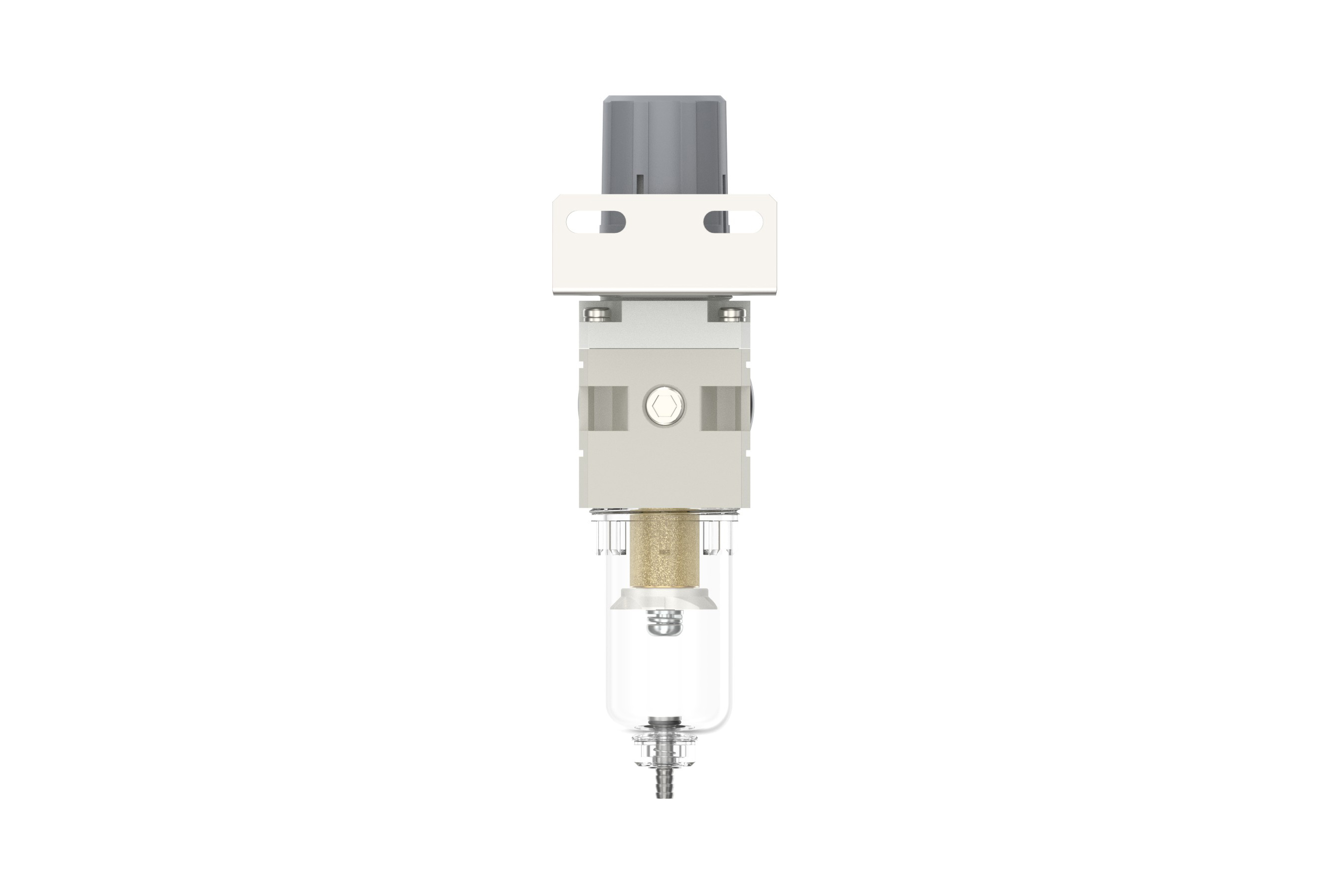

Check that the airflow orientation aligns with the directional indicators on the product casing, and confirm that the port and thread sizes match appropriately.

2. Pressure Adjustment

Raise the pressure gauge knob and start turning it. Turning it to the right will produce a steady and uniform rise in pressure, while turning it to the left will lead to a proportional drop. After reaching the target pressure level, stop turning and firmly secure the knob. If the knob isn't locked correctly, it might cause leakage problems, undermining the system's stability.

3. Dial Reading

5-Micron Brass Filter Element: Offers outstanding filtration performance, enhanced durability, and the ability to be reused multiple times.

0.5 and 0.01-Micron Filter Elements: Effectively capture tiny contaminants.

The drainage column is equipped with a self-acting system. It opens to release substances when there is no pressure and closes when air passes through. Once the water level surpasses the set maximum threshold, prompt drainage is essential; otherwise, the dehumidification efficiency will significantly decline.

4. Drainage

The drainage column features a self - operating mechanism. It unlocks to discharge collected materials when pressure is not present and shuts tightly as air circulates. Once the water level hits or goes beyond the permitted maximum, immediate draining is crucial; neglecting this will cause reduced dehumidification efficiency.

The connector on the drain head functions as a uniform attachment spot for air hoses and can be removed according to particular operating needs or system setups.

Employ a calibrated torque wrench to fasten the connectors to the designated tightness level to avoid any seepage. When first installing the system, an air - expulsion event might take place. This is not a leakage; instead, it stems from the pressure difference between the inside and outside, requiring the release of surplus air. In these circumstances, let the system settle for a suitable period, after which it will function as expected.