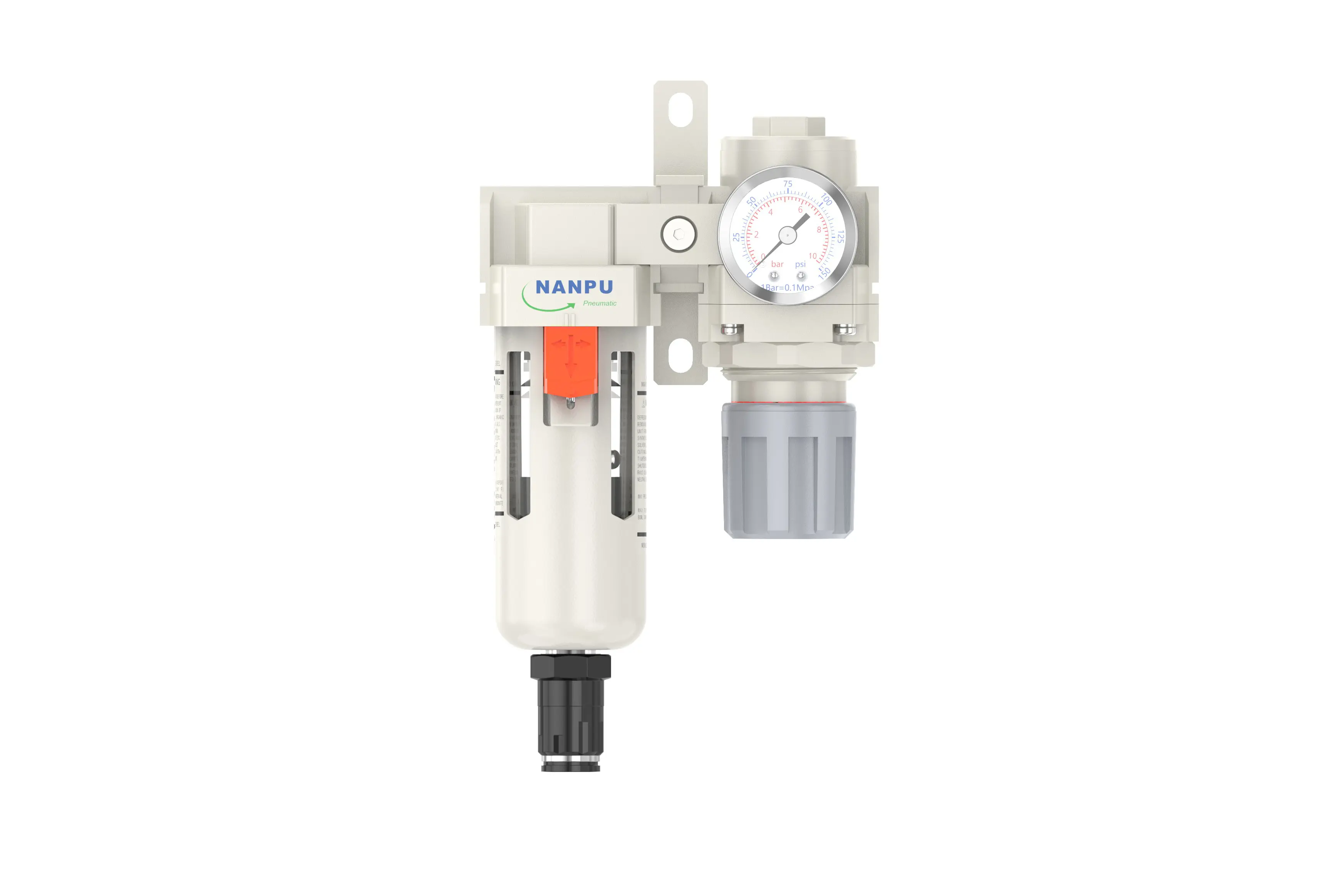

ARF3000-03/ARF4000-04/ARF4000-06 AW Filter Regulator

description1

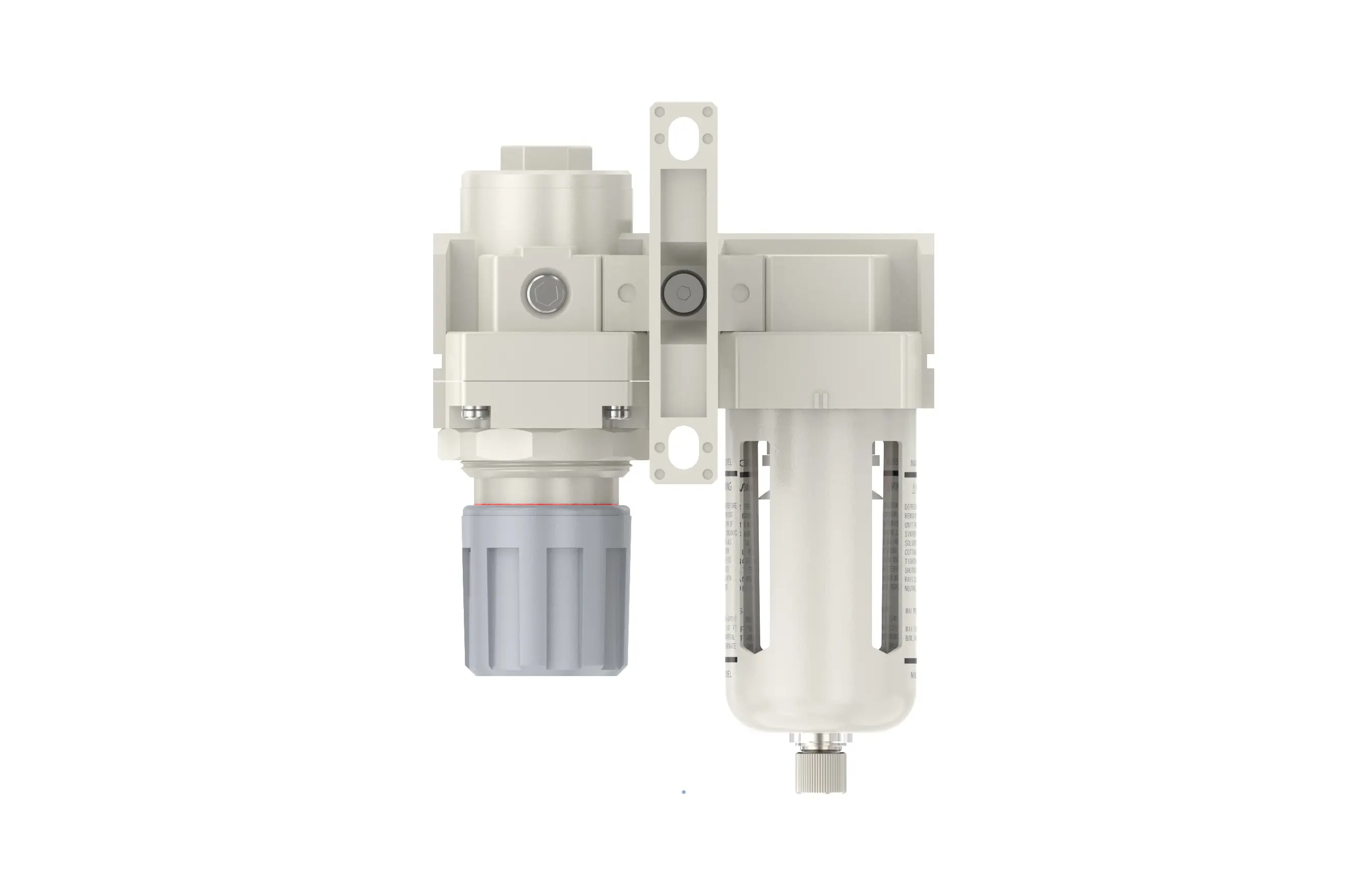

ARF3000-03/ARF3000-03D/ARF4000-04/ARF4000-04D/ARF4000-06/ARF4000-06D AW Filter Regulator

Manual Drain ARF3000-03/ARF4000-04/ARF4000-06 Portsize:3/8" 1/2" 3/4" AW Filter Regulator

Auto Drain ARF3000-03D/ARF4000-04D/ARF4000-06D Portsize:3/8" 1/2" 3/4" AW Filter Regulator

NANPUARF3000-03/ARF4000-04/AW4000-06

| ARF | 3000 | 03 | BSP | D |

| Series Number | Body Size | Port Size | Thread Type | Drainage Method |

| 2000 | 02:1/4" | BSP | Blank: Differential Pressure Drain | |

| 3000 | 03:3/8" | NPT | A: Manual Drain | |

| 4000 | 04:1/2" | PT | D: Auto Drain | |

| 4000/5000 | 06: 3/4" | |||

| 5000 | 10: 1" |

NANPUTechnical Specifications

| Model | Model | |

| Manual Drain | Auto Drain | (L/min)Rated Flow Rate |

| ARF2000-02 | ARF2000-02D | 500 |

| ARF3000-02 | ARF3000-02D | 2000 |

| ARF3000-03 | ARF3000-03D | 2000 |

| ARF4000-04 | ARF4000-04D | 4000 |

| ARF4000-06 | ARF4000-06D | 4500 |

| ARF5000-06 | ARF5000-06D | 5000 |

| ARF5000-10 | ARF5000-10D | 5000 |

| Max Input Pressure | 1.2Mpa{12.24kgf/cm²} /174.04Psi |

| Max Operating Pressure | 1.0Mpa{10.2kgf/cm²} /145Psi |

| Temperature Range | 5~60℃ |

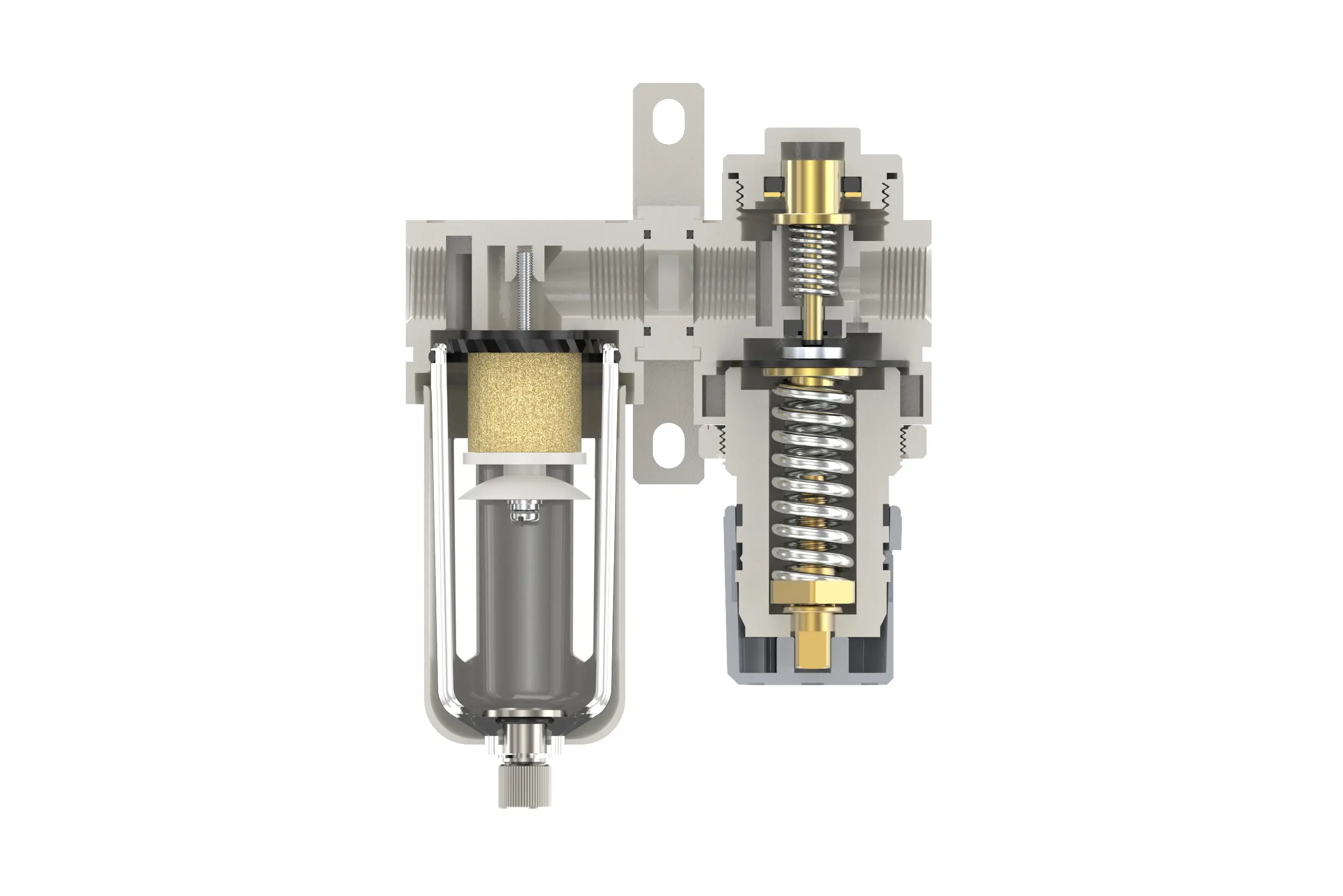

| Filtration Accuracy | 0.01μm, 5μm, 40μm |

| Bowl Material | Polycarbonate |

| Bowl Guard | AC2000(None) AC3000~5000(YES) |

| Pressure Range | AC2000~5000/0.05~0.85Mpa (0.51~8.7kgf/cm² )/0~125Psi |

1. Preparation

Every calibration assembly must meet the maximum flow rate requirements.

Prior to installation, thoroughly scrub the ports and connectors to efficiently stop debris from entering the air conduit.

Check that the airflow orientation corresponds to the arrow signs on the product casing, and confirm that the port and thread sizes are correctly coordinated.

2. Pressure Adjustment

Raise the pressure gauge knob and start turning. Turning it in a clockwise direction will bring about a steady rise in pressure, while turning it counterclockwise will lead to a reduction. After reaching the target pressure level, stop turning and firmly lock the knob. If this locking step is not carried out properly, it might result in possible leakage problems.

3. Dial Reading

5-Micron Brass Filter Element: Displays exceptional filtration capabilities, a greatly prolonged operational lifespan, and allows for repeated use.

0.5 and 0.01-Micron Filter Elements: Effectively remove tiny contaminants.

The drainage column functions autonomously. It activates to expel contents when there is no pressure and seals when air flows through. Once the water level surpasses the set maximum, prompt drainage is necessary; failing to do so will diminish dehumidification performance.

4. Drainage

The drainage column features a self - activating system. It will unlock to release contents when pressure is lacking and seal once air passes through. When the water level exceeds the specified maximum, urgent drainage is essential; neglecting this will result in poor dehumidification efficiency.

The connector on the drain head serves as a connection point for air hoses and can be removed according to particular operating needs.

Employ a correctly sized wrench to tighten the connectors to the required torque level to avoid seepage. When initially installing, an air - evacuation event might take place. This is not a leak; instead, it stems from the pressure difference between the inner and outer conditions, requiring the release of extra air. In these situations, let the system settle for a sufficient time, after which it will function at its best.